Insay di wɔl fɔ plaba, impɔtant tul dɛn de we de ple yunik ɛn impɔtant wok fɔ mek wata kɔntinyu fɔ flɔ insay paip. Pan dɛn tul dɛn ya, tu tin dɛn we dɛn kin kɔnfyus bɔku tɛm kin tinap tranga wan: fitin ɛn adapt dɛn. Pan ɔl we sɔm tɛm dɛn kin yuz dɛn wɔd ya fɔ chenj dɛnsɛf, i rili impɔtant fɔ ɔndastand se dɛn difrɛn ɛn dɛn de sav spɛshal wok dɛn na di plaba sistɛm dɛn.

Insay dis atikul, wi go dayv insay di klia difrɛns bitwin fitin ɛn adapt, shed layt pan dɛn yon rol dɛn na plaba ɛn haydrolik sistem. Ilɛksɛf yu na studɛnt we de lan bɔt plaba ɔ pɔsin we want fɔ no mɔ, we dis atikul dɔn, yu go ɔndastand dɛn impɔtant pat dɛn ya na di plaba pazl. Lɛ wi fɛn di wɔl fɔ fitin ɛn adapt dɛn togɛda!

Wetin na fitin dɛn?

Insay di eria fɔ haydrolik sistem, fitin dɛn na di hiro dɛn we dɛn nɔ siŋ fɔ di haydrolik sistem dɛn, we de sav as di impɔtant kɔnɛkta dɛn we de briŋ di wan ol sɛtup to layf. Ilɛksɛf na split flɔ kɔntrol, ɛleveshɔn ajɔstmɛnt, ɔ prɛshɔn rigyuleshɔn, fitin dɛn de ple wan impɔtant pat fɔ mek shɔ se di efyushɔn ɛn rilaybiliti fɔ di haydrolik ikwipmɛnt dɛn efyushɔn ɛn rilaybiliti.

Difinishɔn ɛn di rizin we mek dɛn mek am .

Fitins, in di konteks of haydrolik sistem, na di kor komponent dem we rispansabl fo mek sho se wan sikyu konekshon bitwin difren konduit, lek hos en tiub. di men tin we dɛn de du na fɔ mek i izi fɔ mek di wata we de kɔmɔt na di haydrolik nɔ flɔ ɛn nɔ gɛt ɛni lik ɔ di prɛshɔn we nɔ fayn fɔ mek i chenj. Pik dɛn as di impɔtant link bitwin di haydrolik yunit ɛn di plaba ikwipmɛnt.

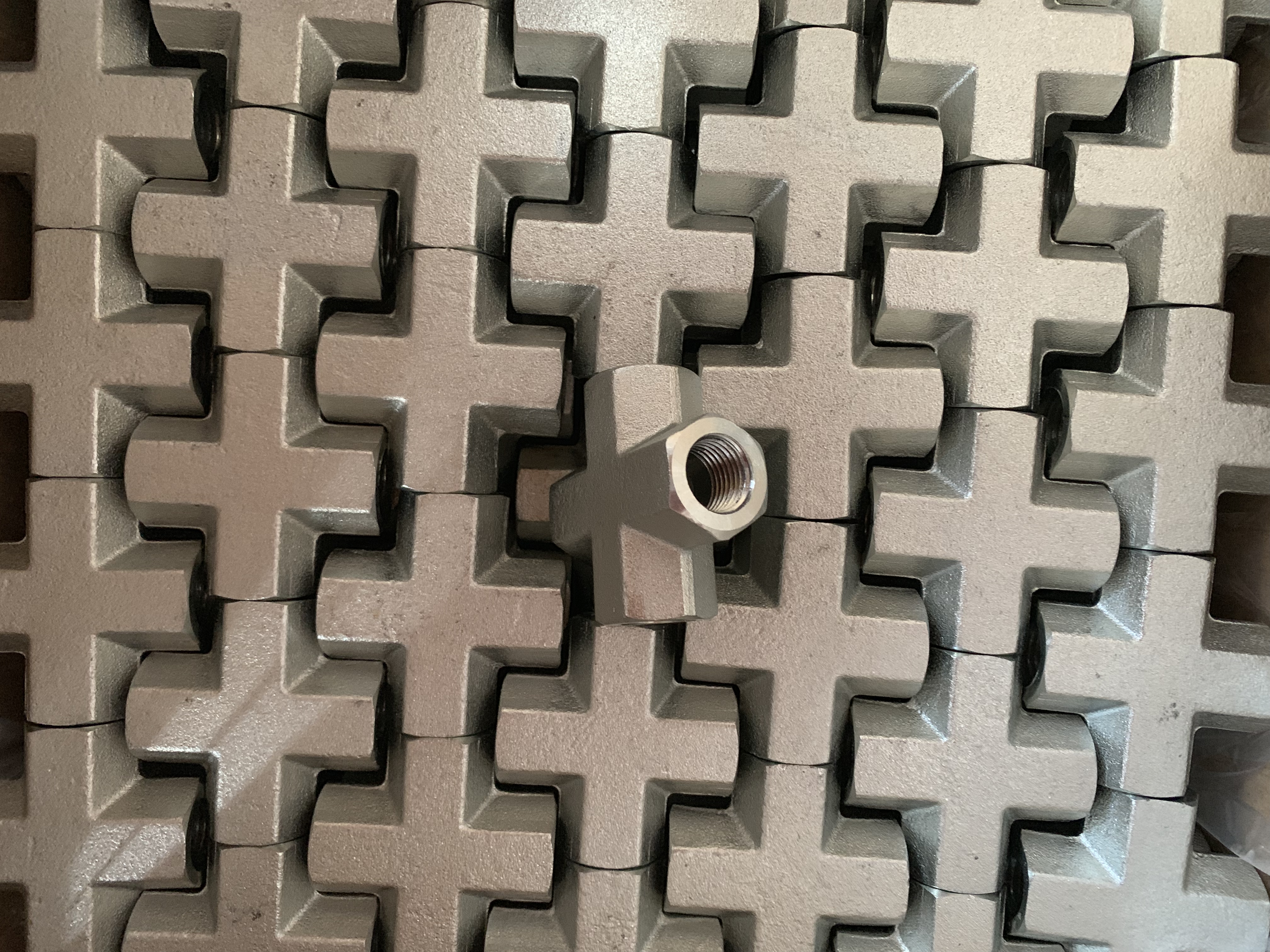

Fitins, we dɛn kin mek bɔku tɛm frɔm industrial-strɛng matirial fɔ mek dɛn go ebul fɔ abop pan am, de wok as di sɛntral pat dɛn we de mek wan haydrolik sistɛm gɛt wanwɔd. Na dɛn na di men tin dɛn we gɛt fɔ du wit kɔnɛktin had mashin pat dɛn, link mashin kɔmpɔnɛnt dɛn, ɛn jɔyn mashin ɛlimɛnt dɛn. In essential, fitin na di kor konekshon we de mek haydrolik sistem de wok seamlessly.

Di kayn fitin dɛn .

Naw we wi dɔn ɔndastand di impɔtant tin dɛn we fitin dɛn gɛt, lɛ wi fɛn di difrɛn difrɛn land skay fɔ di haydrolik fitin dɛn, ɛni wan pan dɛn na fɔ sɔm patikyula wok dɛn. Pan di bɔku bɔku fitin dɛn, tri notabɛl kayn dɛn tinap aut: ORB, JIC, ɛn man-to-man kɔnɛkshɔn.

L orb (O-Ring Boss) Fitins: Dɛn fitin ya dɛn mek wit orb ɛnd ɛn adara to ORB standad. Dɛn kin kam insay difrɛn mɛzhɔmɛnt dɛn, ɛn mek shɔ se dɛn kɔmpit wit difrɛn kɔmpɔnɛnt dɛn. Orb Fittings na di go-to choice wen yu nid wan reliable en lik-fri konekshon.

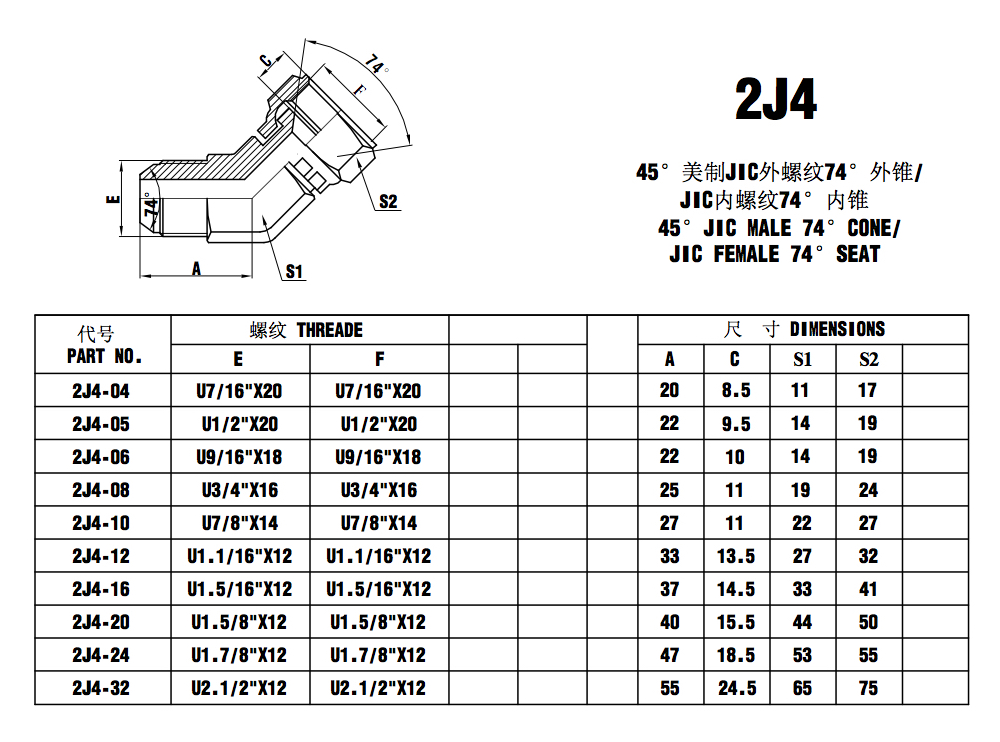

L JIC (Joint Industry Council) Fitins: JIC Fitins Ficha JIC Ends ɛn kɔnfɔm to JIC standad. Dɛn prɛsis mɛzhɔmɛnt dɛn de mek dɛn fayn fɔ aplikeshɔn usay wan sikrit ɛn standad kɔnɛkshɔn na di men tin. JIC fitin na stepul in haydrolik sistem fɔ dɛn kɔmpitibliti ɛn efyushɔn.

l Male-to-male konekshon: Dis fitin dem de fasilit konekshon bitwin man komponent en dem de govan bai indastri standad. Dɛn de gi dɛn versatility ɛn rilaybiliti, we de mek dɛn bi valyu chus insay difrɛn haydrolik sɛtup dɛn.

Praktikal Aplikeshɔn dɛn .

Fɔ rili ɔndastand di minin fɔ fitin, lɛ wi chɛk dɛn insay akshɔn tru prɛktikal ɛgzampul ɛn kes stɔdi. Fitin dɛn fɛn dɛn aplikeshɔn insay bɔku bɔku sɛnɛriɔ, mek shɔ se di haydrolik sistem dɛn go wok fayn fayn wan.

Kes Stɔdi 1: Split Flɔ Kɔntrol .

Imajin wan haydrolik sistem usay nid de kam fɔ split di flɔ we di haydrolik fluid de flɔ na difrɛn say dɛn. Na ya, fitin dɛn kin kam insay bay we dɛn alaw fɔ instɔl branch tiub dɛn, ɛn mek shɔ se dɛn kɔntrol di rayt we fɔ sheb di wata we de kɔmɔt na di wata. Dis aplikeshɔn de sho di adaptabiliti ɛn versatility fɔ fitin dɛn.

Kes Stɔdi 2: Ɛleveshɔn ajɔstmɛnt .

Insay sɔm sityueshɔn dɛn, haydrolik sistɛm dɛn nid chenj dɛn na di ɛleveshɔn fɔ tub layn dɛn fɔ akɔmod difrɛn layout dɛn. Fitins, wit dɛn abiliti fɔ kɔnɛkt plaba na difrɛn angul ɛn ɛleveshɔn, ɛnabul seamlɛs ajɔstmɛnt dɛn we nɔ go kɔmprɔmis di sistɛm in intagriti. Dis de sho dɛn impɔtant wok fɔ adap to difrɛn opareshɔnal nid dɛn.

Kes Stɔdi 3: Prɛshɔn Rɛgyuleshɔn .

Hydraulic systems kin gɛt prɔblɛm dɛn we gɛt fɔ du wit prɛshɔn chenj chenj. Fitins, prɛsishɔnli ɛnjɛnɛri fɔ kɔnɛkt paip ɛn hos sikrit wan, kɔntribyut fɔ mentɛn kɔnsistɛns fluid flɔ ɛn mitigate prɛshɔn vɛryushɔn. Dɛn rilaybiliti na impɔtant tin fɔ mek shɔ se di haydrolik ikwipmɛnt dɛn stebul.

Wetin na di adapt dɛn?

Naw, lɛ wi tɔn wi atɛnshɔn to adapt dɛn na di eria fɔ haydrolik sistɛm dɛn. Adapta, lɛk fitin, na impɔtant pat dɛn, bɔt dɛn gɛt difrɛn kwaliti dɛn ɛn dɛn de sav yunik wok dɛn. Insay dis sɛkshɔn, wi go delv insay di difinishɔn, di funkshɔnaliti, di kayn dɛn, ɛn di rial-wɔl aplikeshɔn dɛn fɔ di adapt dɛn.

Difinishɔn ɛn funkshɔnaliti .

Adapta na di kɔr komponent dɛn na haydrolik sistem, we dɛn mek fɔ mek kɔnɛkshɔn bitwin difrɛn-sayz trɛd ɛn kɔmpɔnɛnt dɛn. Pan ɔl we dɛn wok kin tan lɛk fitin fɔs, di adapt dɛn gɛt wan patikyula rizin ɛn strɔkchɔral mek-ap we de mek dɛn difrɛn.

Di funkshɔnaliti fɔ adapt dɛn de insay dɛn abiliti fɔ brij di gap bitwin kɔmpɔnɛnt dɛn we go tipikul fɔ bi inkɔmpatibl bikɔs ɔf difrɛns dɛn na trɛd saiz ɔ standad. Nɔ lɛk fitin, we de fɔs fɔ pe atɛnshɔn pan sikyɔriti kɔnɛkshɔn insay wan haydrolik sistɛm, adapt dɛn step insay we nid de fɔ kɔnɛkt haydrolik kɔmpɔnɛnt dɛn we gɛt difrɛn saiz ɛn kayn dɛn. Tink bɔt dɛn as di fasilitatɔ dɛn fɔ intachɛnjabiliti na plaba ɛn haydrolik sistɛm.

Tayp ɛn Yuz dɛn fɔ Adapt dɛn .

Adapta dɛn kin kam insay difrɛn we dɛn fɔ kia fɔ di difrɛn nid dɛn we di haydrolik sistem dɛn gɛt. Tri notabɛl kayn dɛn na T-shaped adapt, krɔs-shep adapt, ɛn tu-ɛnd adapt.

L T-shaped adapters: Dɛn adapt ya tan lɛk di lɛta 't' na dɛn strɔkchɔ ɛn dɛn kin yuz dɛn we dɛn nid fɔ branch kɔnɛkshɔn. Dɛn de mek am izi fɔ mek dɛn mek bɔku bɔku rod dɛn insay wan haydrolik sistɛm, we de alaw fɔ mek wata kɔmɔt na difrɛn say dɛn. T-shaped adapters na wan versatil choice fɔ kɔmpleks plaba sɛtup dɛn.

l Krɔs-shep adapt: krɔs-shep adapt dɛn gɛt wan strɔkchɔ we tan lɛk krɔs, we de gi 4 kɔnɛkshɔn pɔynt dɛn. Dɛn nɔ gɛt valyu we bɔku bɔku kɔmpɔnɛnt dɛn nid fɔ kam togɛda na wan jɔnkshɔn. Krɔs-shaped adapt dɛn de mek shɔ se di wata we de kɔmɔt na di wata flɔ fayn fayn wan ɛn dɛn kin yuz am fɔ wok insay intrikɛt haydrolik kɔnfigyushɔn dɛn.

l Tu-ɛnd adapt: As di nem sho, tu-ɛnd adapt dɛn de gi kɔnɛkshɔn na ɔl tu di ɛnd dɛn. Dɛn de sav as brij bitwin kɔmpɔnɛnt dɛn wit difrɛn trɛd saiz dɛn, fɔ mek shɔ se dɛn kɔmpit ɛn fɔ mek dɛn ebul fɔ asembli di haydrolik sistem dɛn wit izi.

Di yus dɛm fɔ adapt dɛn de ɛkstɛnd to sɛnɛriɔ usay di kɔmpitibliti fɔ di kɔmpɔnɛnt dɛn na paramawnt. Fɔ ɛgzampul, we dɛn de kɔnɛkt wan mɛtrik hos ɛnd to wan BSPP (British standad paralel paip) fitin, dɛn nid fɔ mek wan fayn adapt fɔ brij di gap bitwin dɛn difrɛn standad dɛn ya. Adapta dɛn de wok lɛk intamɛdiɛri, we de alaw kɔmpɔnɛnt dɛn we gɛt difrɛn sayz ɛn kayn dɛn fɔ liv togɛda wit wanwɔd insay wan haydrolik sistɛm.

Adapters in Indastrial Kɔntekst dɛn .

Insay rial-wɔl aplikeshɔn, adapt dɛn kin si dɛnsɛf na di at fɔ industrial haydrolik sistem, we de mek kɔnɛkshɔn bitwin difrɛn kɔmpɔnɛnt standad ɛn saiz dɛn. Lɛ wi fɛn sɔm ɛgzampul dɛn fɔ ɔndastand wetin impɔtant:

Example 1: Machinery asembli

Tink bɔt wan ples usay dɛn de mek tin dɛn we de abop pan haydrolik ikwipmɛnt frɔm difrɛn manifakta dɛn ɔlsay na di wɔl. Dɛn mashin dɛn ya kin fala difrɛn standad dɛn lɛk . SAE, ISO , ɔ mɛtrik mɛzhɔmɛnt dɛn. Adapta dɛn de ple wan impɔtant pat fɔ mek dɛn difrɛn difrɛn tin dɛn ya we nɔ gɛt wan bɔt, ɛn mek shɔ se di haydrolik sistem de wok fayn fayn wan.

Example 2: fild ripɛnt .

Insay mentenɛns ɛn ripa sɛnɛriɔ, fil tɛknishian dɛn kin mit wit haydrolik sistem dɛn bɔku tɛm wit kɔmpɔnɛnt dɛn we gɛt difrɛn trɛd saiz ɛn standad. Adapta dɛn kin kam fɔ ɛp dɛn, ɛn dis kin mek di tɛknishian dɛn ebul fɔ chenj, ripɛnt, ɔ ɔpgrɛd di kɔmpɔnɛnt dɛn we nɔ nid fɔ mek dɛn chenj dɛn bɔku bɔku wan.

Example 3: Intachenjabiliti

Adapta dɛn kin rili impɔtant we di haydrolik sistem dɛn nid fɔ adap to di tin dɛn we dɛn nid fɔ chenj. Dɛn alaw fɔ di intachɛnjabiliti fɔ di kɔmpɔnɛnt dɛn, we mek am pɔsibul fɔ ɔpgrɛd ɔ chenj di sistɛm we nɔ gɛt di kɔst ɛn kɔmplisiti fɔ ɔvahɛl di ɔl sɛtup.

Adapta na di silent hiro dɛm we de brij di gap dɛm insay haydrolik sistem, we de mek kɔnɛkshɔn bitwin kɔmpɔnɛnt dɛm wit difrɛn trɛd saiz ɛn standad. Dɛn versatility, kɔpl wit dɛn rol fɔ mek shɔ se dɛn kɔmpitabl, de mek dɛn impɔtant na di wɔl fɔ plaba ɛn haydroliks.

Klarify di kɔnfyushɔn .

Naw we wi dɔn fɛn di wan wan kwaliti dɛn we fitin ɛn adapt dɛn gɛt, na tɛm fɔ adrɛs di ɛlifant na di rum - di kɔnfyushɔn we kin apin bɔku tɛm bikɔs ɔf dɛn shered tɛminɔlɔji ɛn ɔvalapin fɛnshɔn dɛn. Insay dis pat, wi go delv insay wetin mek dɛn kin mistek kɔl fitin ɛn adapt dɛn bɔku tɛm fɔ wan ɔda ɛn gi kɔmparativ analisis fɔ briŋ klia wan to di tin.

Wetin mek fitin ɛn adapt dɛn kin kɔnfyus .

Diskushɔn bɔt shered tɛminɔlɔji ɛn di sem kayn wok dɛn .

Wan pan di praymar rizin fɔ di kɔnfyushɔn we de arawnd fitin ɛn adapt na di yus fɔ shered tɛminɔlɔji ɛn dɛn tan lɛk se na di sem wok dɛn. Haydrolik sistem dɛn bɔku wit tɛminɔlɔji we dɛn kin yuz fɔ chenj dɛnsɛf, we de mek i nɔ izi fɔ difrɛns bitwin di kɔmpɔnɛnt dɛn. Fɔ ɛgzampul, wɔd dɛn lɛk 'Kɔnɛkta,' 'Kɔpla,' ɔ 'Joiners' kin rifer to ɛni wan pan di fitin ɔ adapt, we kin kɔntribyut to di miks-ap.

Pantap dat, ɔl tu di fitin ɛn adapt dɛn de ple impɔtant pat dɛn na di haydrolik sistem dɛn bay we dɛn de kɔnɛkt difrɛn kɔmpɔnɛnt dɛn. Dɛn tan lɛk di hiro dɛn we dɛn nɔ siŋ we de mek shɔ se di haydrolik mashin dɛn wok fayn fayn wan. Dis bin sheb rispɔnsibiliti mɔ pan di layn dɛn bitwin dɛn.

kɔmɔn miskɔnsɛpshɔn dɛn na di industri .

Insay di plaba ɛn haydrolik industri, di rɔŋ we aw pipul dɛn kin tink bɔt fitin ɛn adapt dɛn nɔto tin dɛn we nɔ kɔmɔn. Dɛn mistek ya kin kɔmɔt frɔm we dɛn nɔ gɛt dip ɔndastandin bɔt dɛn nyuans dɛn. Sɔm tin dɛn we pipul dɛn kin tink bɔt we dɛn kin tink bɔt na:

l Intachɛnjabl tɛminɔlɔji: Bɔku pipul dɛn kin yuz di wɔd dɛn 'fittings' ɛn 'adapters' intachɛnj, if dɛn tek am se dɛn de sav di sem tin. Wail dem du shere som similarities, as wi don explor, dem get difren functions en aplikeshon.

l Biliv insay yunivasal kɔmpitibliti: Wan ɔda mistek na di biliv se fitin ɛn adapt dɛn de ɔlsay kɔmpitabl. In rialiti, kompitibiliti dipen pan tin dɛn lɛk thread saiz, standad, ɛn di spɛshal haydrolik kɔmpɔnɛnt dɛn we involv.

l We dɛn nɔ tek di difrɛns dɛn: Sɔm pipul dɛn nɔ kin no di difrɛns bitwin fitin ɛn adapt, dɛn kin tek am se dɛn mek ɔl di kɔnɛkta dɛn ikwal. Dis ovasayt kin lid to inappropriate komponent selekshɔn in haydrolik sistem.

Kɔmparativ analisis .

Sayd-bay-sayd kɔmpiashɔn fɔ fitin ɛn adapt dɛn

Lɛ wi brok di men difrɛns bitwin fitin ɛn adapt dɛn tru wan sayd-bay-sayd kɔmpiashɔn:

Tin |

Fitin dɛn . |

Adapt dɛn . |

Wok |

Kɔnekt hos ɛn tiub dɛn fayn fayn wan. |

Brij kɔnɛkshɔn bitwin kɔmpɔnɛnt dɛn wit difrɛn trɛd saiz ɔ standad. |

Tayp dɛn . |

Difrɛn kayn dɛn fɔ sikyuɔr kɔnɛkshɔn. |

Tayp dɛm lɛk T-shaped, kros-shep, ɛn tu-ɛnd fɔ kɔmpitibliti. |

Yuz 1999. |

Integral fɔ haydrolik fluid flɔ. |

Fasilitayt kɔmpitibliti insay wan haydrolik sistem. |

Tink bɔt |

Kɔnɛkshɔn Sikyuriti. |

Kompatibiliti bitwin difrɛn kɔmpɔnɛnt dɛn. |

Ɛgzampul dɛn . |

JIC, NPT, mɛtrik fitin dɛn. |

Orb, JIC, tu-ɛnd adapt dɛn. |

We fɔ yuz Fittings vs. adapt dɛn na prɛktikal sɛnɛriɔ dɛn .

Fɔ pik bitwin fitin ɛn adapt dɛn na prɛktikal sɛnɛriɔ dipen pan di patikyula nid dɛn fɔ yu haydrolik sistɛm. Na dis na wan prɛktikal gayd:

l Fitins: Opt fɔ fitin dɛn we yu praymar kɔnsyans na sikyuɔr kɔnɛkshɔn bitwin hos, tyub, ɛn haydrolik kɔmpɔnɛnt dɛn. Dɛn fayn fɔ mek di haydrolik fluid flɔ kɔntinyu fɔ flɔ ɛn mek shɔ se wan sikrit kɔndukt.

l Adapta: Yuz adapt we yu nid fɔ brij kɔnɛkshɔn bitwin kɔmpɔnɛnt dɛn we gɛt difrɛn trɛd saiz ɔ standad. Adapta dɛn kin mek dɛn ebul fɔ kɔmpit, we kin mek dɛn impɔtant we dɛn de dil wit difrɛn difrɛn haydrolik kɔmpɔnɛnt dɛn.

Pan ɔl we fitin ɛn adapt dɛn de sheb tɛminɔlɔji ɛn dɛn gɛt sɔm tin dɛn we fiba, dɛn gɛt difrɛn wok dɛn na haydrolik sistem. Fɔ ɔndastand dɛn difrɛns ya rili impɔtant fɔ mek dɛn pik di rayt tin dɛn we dɛn fɔ pik we dɛn de gɛda di haydrolik sistem ɛn avɔyd di kɔmɔn mistek dɛn we dɛn kin tink bɔt na di industri.

Di bɛst we fɔ du tin ɛn di tin dɛn we yu fɔ tink bɔt .

Insay di wɔl fɔ haydrolik sistem, fɔ pik di rayt haydrolik aksesɔri na di men tin fɔ mek shɔ se di wok fayn ɛn sef fayn. Ilɛksɛf yu de pik fitin ɔ adapt, dɛn fɔ tek sɔm tin dɛn na kɔnsidɛreshɔn fɔ mek dɛn disayd fɔ du di rayt tin.

Fɔ pik di rayt haydrolik aksesɔri .

Factors fɔ tink bɔt we yu de pik fitin dɛn .

We i kam pan fitin, dɛn tin ya fɔ gayd di we aw yu de pik di tin dɛn we yu want:

l Kɔmpatibiliti: Pe klos atɛnshɔn to di kayn trɛd, di we aw dɛn de sial, ɛn di tɔk we dɛn nid. Fɔ mek shɔ se di fitin ɛn ɔda haydrolik kɔmpɔnɛnt dɛn go gri wit wetin dɛn de du, na impɔtant tin fɔ mek di lik ɛn prɛshɔn chenj chenj.

L Material: Di matirial fɔ di fitin de ple wan impɔtant pat pan in pefɔmɛns. Opt fɔ industrial-strɛng matirial dɛn we dɛn sabi fɔ dɛn kwaliti ɛn rilaybiliti. Dis de mek shɔ se di fitin kin ebul fɔ bia wit di tin dɛn we yu haydrolik sistem want.

l Kes Stɔdi: Ifɛktiv yus insay haydrolik sistɛm: fɔ lan frɔm rial-wɔl ɛgzampul kin bi inkridibul insaytful. Ɛksplɔr kes stɔdi dɛn we de sho di fayn we aw dɛn de yuz fitin dɛn na haydrolik sistem dɛn. Dɛn stori ya kin gi valyu lɛsin ɛn inspɛkshɔn fɔ yu yon prɔjek dɛm.

Factors fɔ tink bɔt we yu de pik adapt dɛn .

Semweso, di wan dɛn we de yuz di adapt dɛn nid fɔ tek tɛm tink bɔt dɛn tin ya bay di tin dɛn we de dɔŋ ya:

l Kɔmpatibiliti: Jɔs lɛk fitin, adapt dɛn fɔ kɔmpit wit di kɔmpɔnɛnt dɛn we dɛn kɔnɛkt. Dis inklud thread saiz, silin we, ɛn komponent standad. Ɔltɛm, chɛk fɔ no if pɔsin go kɔmpit bifo yu instɔl am.

l Material: Di matirial fɔ adapt dɛn impɔtant lɛk di wan fɔ fitin dɛn. Pik adapt dɛn we dɛn mek wit ay kwaliti matirial fɔ mek shɔ se dɛn ebul fɔ handle di dimand fɔ kɔnɛkt difrɛn kɔmpɔnɛnt dɛn na yu haydrolik sistem.

l Kes Stɔdi: Ifɛktiv yus insay haydrolik sistem: fɛn kes stɔdi dɛn we de sho saksesful aplikeshɔn dɛn fɔ adapt dɛn na haydrolik sistem dɛn. Dɛn rial ɛgzampul dɛn ya kin gi valyu tin dɛn fɔ no bɔt ustɛm ɛn aw fɔ yuz adapt dɛn fayn fayn wan.

Instɔlɛshɔn ɛn Mentɛnans .

Di bɛst we fɔ du fɔ instɔl haydrolik fitin dɛn .

Di rayt we fɔ instɔl na di men tin fɔ mek di haydrolik fitin dɛn wok ɛn fɔ liv lɔng. Fɔ fala dɛn bɛst we ya:

l Sikyu Kɔnɛkshɔn: Mek shɔ se wan sikrit kɔnɛkshɔn bitwin hos, tyub, ɛn haydrolik kɔmpɔnɛnt fɔ mek i nɔ lik ɛn fɔ mek di haydrolik nɔ flɔ. Yuz di rayt tɔk fɔ ajɔst dis.

l Thread compatibility: Verifay se di threads pan di fitin mach di wan dem na di komponent dem we yu de konekt. Di trɛd dɛn we nɔ mach kin mek dɛn gɛt kɔmpitishɔn prɔblɛm ɛn dɛn kin pwɛl.

Di bɛst we fɔ instɔl haydrolik adapt dɛn .

We i kam pan fɔ instɔl haydrolik adapt dɛn, di sem kayn bɛst we fɔ du tin kin apin:

l Sikyu Brij: Adapta dɛn fɔ sikyuɔri brij kɔnɛkshɔn bitwin kɔmpɔnɛnt dɛn wit difrɛn trɛd saiz ɔ standad. Dabl-chɛk se di adapt fit ɔl tu di kɔmpɔnɛnt dɛn fayn fayn wan.

l Thread compatibility: Jɔs lɛk aw i bi wit fitin, kɔnfɔm se di adapt in trɛd dɛn kɔmpitabl wit di kɔmpɔnɛnt dɛn we i kɔnɛkt.

Mentɛnans tips fɔ lɔng layf ɛn sefty .

Fɔ mek shɔ se yu gɛt lɔng tɛm pefɔmɛns ɛn sef fɔ yu haydrolik sistɛm, fala dɛn mentenɛns tips ya:

l ɔltɛm inspɛkt fitin ɛn adapt fɔ sayn dɛn fɔ wɛr, damej, ɔ lik.

l Riples ɛni komponent we de sho sayn fɔ wɛr ɔ damej kwik kwik wan.

l Kip di haydrolik kɔnɛkshɔn klin ɛn nɔ gɛt dɔti fɔ mek i nɔ klos ɔ pwɛl.

Fɔ sɔlv prɔblɛm dɛn we kin apin kɔmɔn tin dɛn .

If tin apin wit yu haydrolik kɔnɛkshɔn, tink bɔt di kɔmɔn tin dɛn we yu fɔ du fɔ sɔlv prɔblɛm dɛn:

l Chɛk fɔ si if di kɔnɛkshɔn nɔ gɛt bɛtɛ kɔnekshɔn ɛn dɛn dɔn tayt dɛn bak as nid de.

l Verifay se ɔl di komponent dɛn dɔn instɔl kɔrɛkt wan ɛn kɔmpitabl.

l Adrɛs ɛni lik wantɛm wantɛm fɔ mek yu nɔ pwɛl yu haydrolik sistem.

Fɔ pik di rayt haydrolik aksesɔri, ilɛksɛf na fitin ɔ adapt, i nid fɔ ɔndastand di kɔmpitibliti, di kwaliti kwaliti, ɛn di bɛst we fɔ instɔl ɛn mentenɛns. We yu fala dɛn tin ya we yu fɔ tink bɔt ɛn lan frɔm di rial wɔl kes stɔdi dɛn, yu kin mek shɔ se yu gɛt fayn fayn opareshɔn ɛn lɔng layf fɔ yu haydrolik sistem dɛn.

Ruihua Industrial Hose & Fittings - Yu trɔst prɔvayda we yu trɔst

Na Ruihua Industrial Hose & Fittings, wi tek prayz fɔ bi yu trɔst prɔvayda fɔ ɔl yu haydrolik fitin ɛn adapt nid. Wit wan komitment fɔ kwaliti, wan rich kɔstɔm sɔlvishɔn, ɛn wan dedikeshɔn to top-notch kastoma savis, wi de ya fɔ mit yu yunik rikwaymɛnt dɛn na di wɔl fɔ haydrolik sistɛm dɛn.

Wi renj fɔ haydrolik fitin ɛn adapt dɛn .

We i kam pan haydrolik fitin ɛn adapt, wi de gi wan kɔmprɛhɛnsif rɛnj we dɛn mek fɔ kia fɔ difrɛn aplikeshɔn dɛn. Ilɛksɛf yu nid fitin fɔ paip, hos, ɔ kɔmpɔnɛnt, wi dɔn kɔba yu. Dɛn mek wi fitin dɛn fɔ mek shɔ se dɛn gɛt sikrit kɔnɛkshɔn, mek dɛn nɔ lik, ɛn mek am izi fɔ mek di haydrolik flɔ fayn fayn wan. Wi ɔndastand di impɔtants fɔ kɔmpitibliti ɛn gi sɔlvishɔn dɛn we de mek yu haydrolik sistɛm wan nɔ gɛt wan prɔblɛm.

Kastom Sɔlwɛshɔn fɔ Yunik Rikwaymɛnt dɛn .

Wi no se nɔto ɔl di haydrolik sistem dɛn mek ikwal. Na dat mek wi spɛshal fɔ gi kɔstɔm sɔlvishɔn fɔ mit yu yon rikwaymɛnt dɛn. Ilɛksɛf yu nid fitin dɛn we gɛt spɛshal trɛd saiz, adapt fɔ di kɔmpɔnɛnt standad dɛn we nɔ kɔmɔn, ɔ we dɛn mek fɔ sɔlv di prɔblɛm dɛn fɔ kɔmpleks plaba sɛtup dɛn, wi tim fɔ ɛkspɛkt dɛn dɔn rɛdi fɔ ɛp yu. Wi biliv fɔ go di ekstra mayl fɔ mek shɔ se yu haydrolik sistem de wok fɔ flawlɛs.

Kɔmitmɛnt fɔ Kwaliti ɛn Kastamɔ Savis .

Kwaliti ɛn kastoma savis de na di kɔl fɔ wi valyu dɛn. Wi de sɔs industrial-strɛng matirial fɔ kraft fitin ɛn adapt dɛn we pɔsin kin abop pan ɛn we go de fɔ lɔng tɛm. Wi kɔmitmɛnt fɔ kwaliti de go bifo pas wi prɔdak dɛm; I de sho insay wi ɛksɛpshɔn kastoma savis. Wi de ya fɔ ansa yu kwɛstyɔn dɛn, gi ɛkspɛkt gayd, ɛn ɛp yu fɔ pik di rayt haydrolik aksesɔri fɔ yu nid dɛn. Yu satisfay na wi prɔyoritɛt.

Aw fɔ . Kɔntakt wi fɔ aks kwɛstyɔn ɛn ɔda tin dɛn we wi dɔn ɔda .

Fɔ gɛt kɔntakt wit wi na tin we izi. If yu get kweshon, nid kot, o redi fo mek oda, wi jos bi kol o email away. Rich to wi tim we de wok tranga wan, ɛn wi go gi yu di infɔmeshɔn ɛn ɛp we yu nid. Yu haydrolik fitin ɛn adapt dɛn rikwaymɛnt dɛn de na kapɛbul an wit Ruihua Indastrial Hos & Fitins.

Dɔn

Fɔ dɔn, dis kɔmprɛhɛnsif gayd dɔn go insay di wɔl fɔ haydrolik fitin ɛn adapt, shed layt pan dɛn difinishɔn, tayp, aplikeshɔn, ɛn di ki difrɛns bitwin dɛn. Wi dɔn ɛksplɔrɔ aw fitin dɛn de sav fɔ kɔnɛkt mashin pat dɛn fayn fayn wan to tiub ɛn paip, wit fɔs pan impɔtant chenj dɛn lɛk ORB, JIC, ɛn man-to-man kɔnɛkshɔn.

Adapta dɛn, na di ɔda say, dɛn bin deymtified, dɛn bin de sho dɛn spɛshal strɔkchɔ ɛn wok dɛn we de mek dɛn difrɛn frɔm fitin dɛn. Wi dɔn ɛgzamin difrɛn kayn adapt dɛn, lɛk T-shaped, kros-shep, ɛn tu-ɛnd adapt, ɛn dɛn impɔtant wok dɛn na kɔmpleks plaba sistɛm dɛn.

Fɔ adrɛs kɔmɔn industri kɔnfyushɔn, wi dɔn tɔk bɔt wetin mek fitin ɛn adapt dɛn kin miks bɔku tɛm, klarify miskɔnsepshɔn ɛn gi kɔmparativ analisis fɔ gayd dɛn aprɔpriet yus.

Fɔ di wan dɛn we de luk fɔ di bɛst we fɔ du ɛn tink bɔt, wi dɔn tɔk bɔt tin dɛn fɔ pik di rayt haydrolik aksesɔri, we inklud kɔmpitibliti, matirial, ɛn rial-wɔl kes stɔdi. Apat frɔm dat, dɛn bin prɛzɛnt instɔleshɔn ɛn mentenɛns bɛst prɔsis, wit trɔbulshut tips fɔ wan simlɛs haydrolik sistɛm.

Ruihua Industrial Hose & Fittings dɔn introdyus as yu trɔst prɔvayda, we de gi wan rich haydrolik fitin ɛn adapt, kɔstɔm sɔlvishɔn, unwavering kɔmitmɛnt fɔ kwaliti, ɛn ɛksɛpshɔn kastoma savis. Kontakt wi tide fɔ ɔl yu haydrolik nid dɛm.

FAQs: Fitins ɛn Adapt dɛn .

K: Wetin na di men difrɛns bitwin paip fitin ɛn adapt?

A: Fitins Chenj Flow Direkshɔn; Adapta dɛn kin kɔnɛkt difrɛn kayn dɛn.

K: Yu kin intachɛnj fitin ɛn adapt dɛn na wan plaba sistɛm?

A: Yes, if konekshon taip and saiz dem de mach.

K: Aw yu kin pik di rayt fitin ɔ adapt fɔ wan patikyula aplikeshɔn?

A: Tink bɔt di kɔmpitibliti, prɛshɔn rɛytin, ɛn matirial.

K: Yu tink se standad saiz dɛn de fɔ fitin ɛn adapt dɛn na di industri?

A: Yes, standad de fɔ kɔnsistɛns akɔdin to aplikeshɔn dɛn.

K: Wetin na di sayn dɛm we se fitin ɔ adapt nid fɔ chenj?

A: lik, kɔrɛshɔn, ɔ damej we pɔsin kin si de sho se dɛn dɔn chenj am.

K: Yu tink se adapta kin bi fitin fo som kes?

A: Yes, wen yu de adap and fit funkshon ovalap.

K: Wetin na di bad tin dɛn we kin apin we pɔsin yuz fitin ɔ adapt dɛn we nɔ kɔmpitabl?

A: Lik, sistɛm fɔl, ɔ sefty hazad kin apin.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu