Haydrolik push fitin dɛn dɔn rivɔlɔshɔn di fil fɔ fluid pawa sistem, we de gi wan rilibul ɛn efishɔnal sɔlvishɔn fɔ kɔnɛkt difrɛn kɔmpɔnɛnt dɛn. Insay dis wɔl we pipul dɛn de go fast fast, usay tɛm na di men tin, fɔ ɔndastand di bɛnifit dɛn we haydrolik push fitin dɛn gɛt kin rili impɔtant. Dɛn fitin ya de gi kɔnɛkshɔn we sikrit ɛn we nɔ de lik, we de mek shɔ se di wok fayn fayn wan ɛn we de ridyus di risk fɔ mek yu nɔ gɛt bɔku mɔni. Wit dɛn izi instɔleshɔn prɔses ɛn versatility, haydrolik push fitin dɛn dɔn bi di go-to choice fɔ bɔku industri dɛn, frɔm manufakchurin to kɔnstrɔkshɔn. We dɛn nɔ nid fɔ yuz kɔmpleks tul dɛn ɛn di we aw dɛn kin du tin dɛn we kin tek bɔku tɛm, dɛn fitin dɛn ya kin mek di asembli wok izi, ɛn dis kin mek dɛn nɔ spɛn bɔku tɛm ɛn tin dɛn we dɛn nid. Pantap dat, dɛn ebul fɔ bia wit ay prɛshɔn ɛn tɛmpracha chenj de mek dɛn fayn fɔ dimand aplikeshɔn dɛn. Ilɛksɛf yu na pɔsin we sabi du di wok ɔ yu na nyu pɔsin we sabi du di wok, fɔ ɔndastand di bɛnifit dɛn we haydrolik push fitin dɛn gɛt, impɔtant fɔ mek yu ebul fɔ wok fayn fayn wan ɛn fɔ mek shɔ se yu fluid pawa sistem dɛn go liv lɔng. Insay dis atikul, wi go delv insay di difrɛn bɛnifit dɛn we haydrolik push fitin dɛn gɛt, we go mek wi no se dɛn impɔtant ɛn aw dɛn go mek yu wok fayn.

Ɔndastand di Haydrolik Push Fitin dɛn

Difayn haydrolik push fitin ɛn di wok we dɛn de du

Haydrolik push fitin na impɔtant komponent dɛn na haydrolik sistem we de alaw fɔ di sikyɔriti ɛn rili kɔnɛkshɔn fɔ difrɛn haydrolik kɔmpɔnɛnt dɛn. Dɛn mek dɛn fitin ya fɔ mek kɔnɛkshɔn we nɔ gɛt lik bitwin difrɛn haydrolik hos dɛn, paip dɛn, ɔ tyub dɛn, we go mek shɔ se dɛn transfa haydrolik fluid fayn fayn wan ɛn di sistɛm wok fayn fayn wan.

Di wok we haydrolik push fitin dɛn de du na fɔ jɔyn di haydrolik kɔmpɔnɛnt dɛn togɛda, we de gi tayt sil we de mek di wata nɔ lik ɛn we de mek di haydrolik sistɛm kɔntinyu fɔ wok. Dɛn kin yuz dɛn fitin dɛn ya fɔ du tin dɛn usay dɛn nid fɔ diskɔnekt ɛn kɔnɛkt di haydrolik layn dɛn ɔltɛm, lɛk fɔ yuz kɔnstrɔkshɔn ikwipmɛnt, agrikalchɔral mashin dɛn, ɛn industrial sistem dɛn.

Aw dɛn de wok na haydrolik sistem

Haydrolik push fitin dɛn de wok bay we dɛn de yuz wan simpul yet ifɛktiv mɛkanism fɔ mek wan sikyɔriti kɔnɛkshɔn bitwin haydrolik kɔmpɔnɛnt dɛn. Dɛn fitin ya kin gɛt tu men pat dɛn: wan man kɔnɛkta ɛn wan uman kɔnɛkta. Di man kɔnɛkta gɛt wan ɛnd we gɛt trɛd, we di uman kɔnɛkta gɛt kɔrɛspɔndɛns intɛriɔ we gɛt trɛd.

Fɔ mek kɔnɛkshɔn, dɛn kin put di man kɔnɛkta insay di uman kɔnɛkta ɛn twist am kloksayz te i tayt tayt wan. As di man kɔnɛkta de twist, di trɛd dɛn na di tu kɔnɛkta dɛn de ɛnjɔy, we de mek wan tayt sil. Di we aw dɛn mek di fitin dɛn de mek shɔ se di kɔnɛkshɔn stil sikrit, ivin ɔnda ay prɛshɔn ɛn vaybreshɔn.

Wan pan di men bɛnifit dɛn we haydrolik push fitin dɛn gɛt na we dɛn kin instɔl am kwik ɛn izi. Nɔ lɛk tradishɔnal fitin dɛn we nid fɔ yuz tul ɛn tin dɛn we kin tek bɔku tɛm, dɛn kin yuz an fɔ mek haydrolik push fitin dɛn, ɛn dis kin mek dɛn nɔ spɛn bɔku tɛm ɛn tray tranga wan. Dis kin mek dɛn rili yusful pan aplikeshɔn dɛn usay dɛn nid fɔ mentenɛns ɔ ripɛnt ɔltɛm.

Di kayn haydrolik push fitin dɛn we de

Bɔku kayn haydrolik push fitin dɛn de we dɛn kin yuz, ɛn dɛn mek ɛni wan pan dɛn fɔ kia fɔ sɔm patikyula tin dɛn we dɛn nid ɛn fɔ yuz dɛn. Na sɔm kayn dɛn ya we dɛn kin yuz:

1. Stret fitin : Dɛn fitin ya gɛt stret kɔnfigyushɔn, we de alaw fɔ mek tu haydrolik kɔmpɔnɛnt dɛn gɛt dairekt kɔnekshɔn. Dɛn fayn fɔ aplikeshɔn usay dɛn nid fɔ gɛt stret kɔnɛkshɔn, we nɔ gɛt ɛni angul ɔ bɛnd.

2. Ɛlbo fitin : Dɛn mek ɛlbo fitin wit 90 digri bɛnd, we de alaw fɔ chenj di dairekshɔn fɔ di haydrolik layn. Dɛn kin yuz dɛn na say dɛn we tayt ɔ we dɛn nid fɔ mek di haydrolik layn dɛn go rawnd tin dɛn we de ambɔg dɛn.

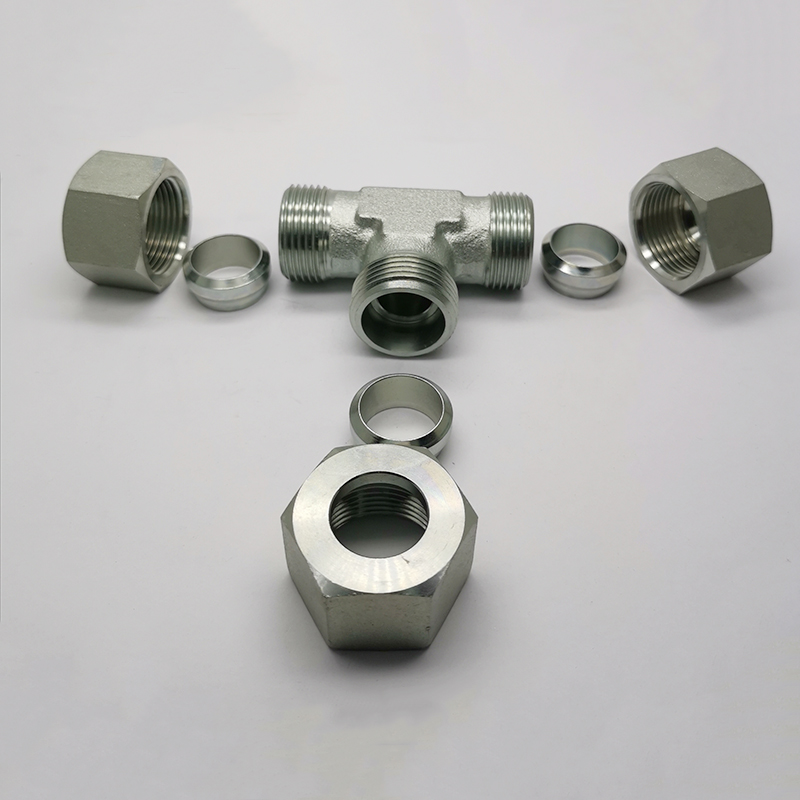

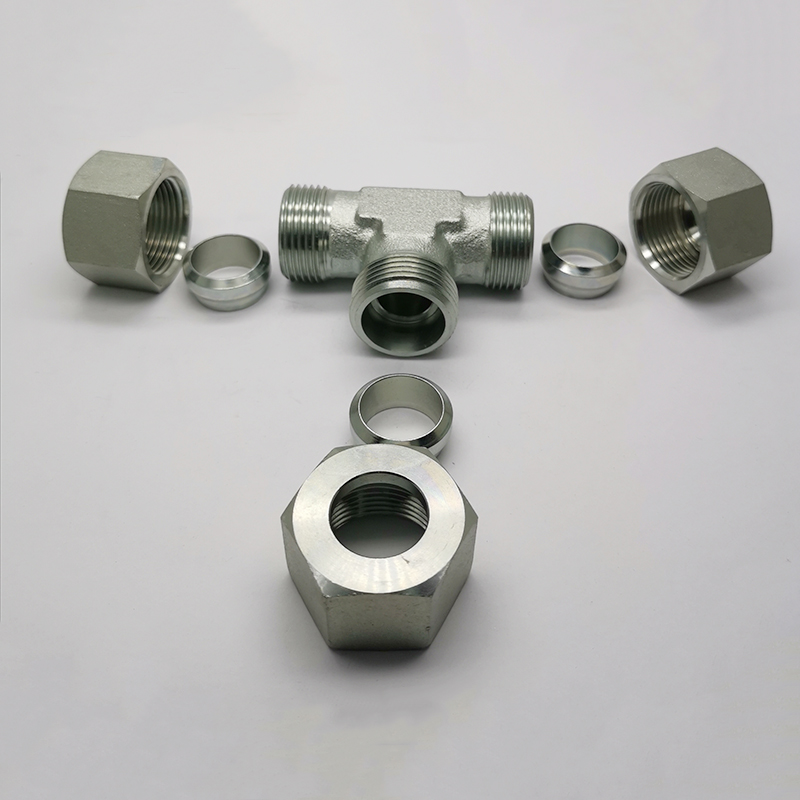

3. Ti fitin : Ti fitin gɛt T-shaped dizayn, we de mek yu ebul fɔ kɔnekshɔn tri haydrolik kɔmpɔnɛnt dɛn. Bɔku tɛm dɛn kin yuz dɛn we nid fɔ mek branch ɔ divayd haydrolik layn dɛn, lɛk na haydrolik sistem dɛn we gɛt bɔku aktyuator dɛn.

4. Ridyus fitin : Dɛn kin yuz ridyus fitin fɔ kɔnɛkt haydrolik kɔmpɔnɛnt dɛn we gɛt difrɛn saiz ɔ dayamita. Dɛn gɛt difrɛn saiz opin dɛn na ɛni ɛnd, we de mek dɛn ebul fɔ chenj fayn fayn wan bitwin tu haydrolik layn dɛn we gɛt difrɛn saiz dɛn.

5. Bulkhead fittings : Dɛn mek bulkhead fittings spɛshal fɔ aplikeshɔn usay haydrolik layn nid fɔ pas tru panɛl ɔ barɛri. Dɛn de gi kɔnɛkshɔn we sikrit ɛn we nɔ de lik ɛn dɛn de mek di panɛl kɔntinyu fɔ wok fayn.

Advantej dɛn fɔ Haydrolik Push Fitin dɛn

A. I izi fɔ instɔl

Haydrolik push fitin dɛn de gi bɔku bɛnifit dɛn, frɔm we i izi fɔ instɔl. Di simpul ɛn spid we di instɔleshɔn prɔses de mek de mek dɛn lɛk fɔ pik dɛn na difrɛn industri dɛn. Difrɛn frɔm tradishɔnal fitin dɛn, haydrolik push fitin dɛn de mek dɛn nɔ nid spɛshal tul dɛn, ɛn dis kin mek dɛn nɔ spɛn bɔku tɛm ɛn trɛnk we dɛn de gɛda dɛn. Wi jɔs push ɛn klik, dɛn fitin dɛn ya kin kɔnɛkt tub ɛn hos dɛn fayn fayn wan, ɛn dis kin mek shɔ se dɛn gɛt haydrolik sistem we pɔsin kin abop pan ɛn we kin wok fayn.

B. Kɔnɛkshɔn dɛn we Nɔ Gɛt Lik

Insay haydrolik sistem, kɔnɛkshɔn dɛn we nɔ gɛt lik na dɛn impɔtant pas ɔl fɔ mek dɛn kɔntinyu fɔ wok fayn fayn wan. Haydrolik push fitin dɛn fayn fɔ gi rili silin, we de mek di risk fɔ lik nɔ bɔku. Dis kin apin tru dɛn nyu dizayn ficha dɛn, lɛk O-ring ɛn kɔmpreshɔn ring. Dɛn komponent ya de mek wan tayt ɛn sikrit kɔnekshɔn, we de mek ɛni fluid nɔ lik. Bay we dɛn de mek shɔ se kɔnɛkshɔn dɛn we nɔ gɛt lik, di haydrolik push fitin dɛn de kɔntribyut to di ɔvala efyushɔn ɛn lɔng layf fɔ di haydrolik sistem dɛn.

C. Versatility ɛn Kɔmpatibiliti

Wan pan di men bɛnifit dɛn we haydrolik push fitin dɛn gɛt na we dɛn kin yuz bɔku tin dɛn ɛn dɛn kin wok togɛda. Dɛn fitin ya kin yuz insay bɔku bɔku aplikeshɔn dɛn akɔdin to difrɛn industri dɛn. Ilɛksɛf na motoka, kɔnstrɔkshɔn, ɔ manufakchurin, haydrolik push fitin dɛn pruv fɔ adap to difrɛn sistɛm rikwaymɛnt dɛn. Apat frɔm dat, dɛn kin wok wit difrɛn kayn tub ɛn hos dɛn, lɛk polyethylene, naylon, ɛn polyurethane. Dis kɔmpatibiliti de alaw fɔ intagret seamles insay di haydrolik sistem dɛn we de naw, we de ridyus di nid fɔ kɔst modifyeshɔn ɔ riplesmɛnt.

D. Di we aw pɔsin kin spɛn bɔku mɔni

Haydrolik push fitin dɛn de gi bɔku bɛnifit dɛn we de sev mɔni. We dɛn nɔ nid fɔ gɛt ɔda tin dɛn lɛk klem ɛn kɔnɛkta, dɛn fitin dɛn ya de ridyus di ɔl di kɔst fɔ di sistem. Di simpul instɔleshɔn prɔses de sev tɛm ɛn leba ɛkspɛns bak. Pantap dat, di mɔni we dɛn kin sev fɔ lɔng tɛm kin apin bay we dɛn de mek di wok fayn fayn wan ɛn we dɛn nɔ de mek di say dɛn we dɔn pwɛl. Wit lik-fri kɔnɛkshɔn, haydrolik sistem dɛn de wok na dɛn ɔptimal lɛvɛl, we de minimiz di risk fɔ dawt tɛm ɛn kɔst ripɛnt. Di durabiliti ɛn rilaybiliti fɔ haydrolik push fitin dɛn de mek shɔ se wan kɔst-ɛfɛktiv sɔlvishɔn fɔ difrɛn industri dɛn.

E. Fleksibiliti ɛn Riyuzabiliti

Haydrolik push fitin dɛn de gi fleksibiliti we nɔ gɛt wan kɔmpitishɔn fɔ chenj di sistɛm. Insay dinamik industri dɛn usay chenj kin apin bɔku tɛm, dɛn fitin dɛn ya kin gi wan fayn sɔlvishɔn. I izi fɔ pul dɛn ɛn yuz dɛn bak, we kin mek dɛn ebul fɔ ajɔst ɔ chenj dɛn kwik kwik wan. Dis fleksibiliti nɔ jɔs de sev tɛm bɔt i de ridyus di west matirial. We dɛn de yuz fitin dɛn bak, di kɔmni dɛn kin ɛp fɔ mek dɛn ebul fɔ kɔntinyu fɔ de, ɛn dis kin mek dɛn nɔ ambɔg di envayrɔmɛnt. Di abiliti fɔ adap ɛn yuz bak di haydrolik push fitin dɛn de mek dɛn bi valyu prɔpati na industri dɛn we nid fɔ chenj di sistɛm ɔltɛm.

F. Sefty ɛn Rilaybiliti

Sefty impɔtant pas ɔl na haydrolik sistem, ɛn haydrolik push fitin dɛn de gi fayn fayn sef ficha dɛn. Dɛn mek dɛn fitin dɛn ya fɔ bia wit di vaybreshɔn ɛn prɛshɔn we de chenj, ɛn dis go mek shɔ se kɔnɛkshɔn sikrit ivin na say dɛn we tin tranga. Di resistans to vibration de mek di fitin dɛn nɔ lus as tɛm de go, we de mek di bad tin dɛn we kin apin nɔ apin. Apat frɔm dat, di ebul fɔ bia wit prɛshɔn fluktueshɔn de mek shɔ se di haydrolik sistɛm dɛn stebul ɛn rilaybiliti. Wit haydrolik push fitin, di wan dɛn we de wok kin gɛt pis na dɛn maynd we dɛn no se dɛn bil dɛn sistɛm fɔ bia wit di strɔng tin dɛn we dɛn de yuz.

Tin dɛn fɔ Tink Bɔt fɔ Yuz Haydrolik Push Fitin dɛn

A. Prɔpa Sayz ɛn Sɛlɛkshɔn

We i kam pan fɔ yuz haydrolik push fitin, di rayt sayz ɛn sɛlɛkshɔn impɔtant fɔ mek shɔ se di wok fayn fayn wan ɛn fɔ avɔyd prɔblɛm dɛn we kin apin. Fɔ pik di kɔrɛkt saiz ɛn di kayn fitin impɔtant fɔ mek shɔ se kɔnɛkshɔn sikrit ɛn nɔ gɛt lik. I impɔtant fɔ tink bɔt di tin dɛn we di sistɛm nid, inklud di sayz ɛn di kayn tub ɔ hos we dɛn de yuz, ɛn bak di prɛshɔn ɛn tɛmpracha rɛytin.

Fɔ no di rayt fitin saiz, i nid fɔ mɛzhɔ di ɔda dayamita fɔ di tub ɔ hos. Dis mɛzhɔmɛnt go ɛp fɔ pik di fitin wit di kɔrɛspɔndɛns insay dayamita we mach di ɔda dayamita fɔ di tubing ɔ hos. I fayn fɔ luk di manifakta gaydlayn ɔ aks pɔsin we sabi du di wok fɔ mek shɔ se di sayz kɔrɛkt.

Apat frɔm di sayz, dɛn fɔ tek tɛm tink bak bɔt di kayn fitin. Difrɛn kayn haydrolik push fitin dɛn de, lɛk stret fitin, ɛlbo fitin, ti fitin, ɛn krɔs fitin. Ɛni kayn tin de fɔ wan patikyula tin ɛn i de gi difrɛn bɛnifit dɛn. We yu ɔndastand di tin dɛn we di sistɛm nid ɛn di patikyula aplikeshɔn, dat go ɛp fɔ pik di kayn fitin we fit pas ɔl.

Prɛshɔn ɛn tɛmpracha retinj na impɔtant tin dɛn bak we yu fɔ tink bɔt we yu de pik haydrolik push fitin dɛn. Dɛn mek dɛn fitin dɛn ya fɔ bia wit patikyula prɛshɔn ɛn tɛmpracha rɛnj dɛn, ɛn if dɛn pas dɛn limit ya, dat kin mek dɛn nɔ wok ɛn dat kin mek dɛn gɛt prɔblɛm dɛn. I rili impɔtant fɔ mek shɔ se di fitin dɛn we yu dɔn pik go ebul fɔ handle di maksimal prɛshɔn ɛn tɛmpracha na di haydrolik sistɛm fɔ avɔyd ɛni sef risk.

B. Mentɛnans ɛn Inspekshɔn

I impɔtant fɔ mek dɛn mentenɛns ɛn inspɛkt am ɔltɛm fɔ mek di haydrolik push fitin dɛn wok fayn ɛn fɔ mek dɛn liv lɔng. Dis kin ɛp fɔ no ɛni prɔblɛm we kin apin ɔ we kin pwɛl we kin afɛkt dɛn wok. Fɔ klin ɛn lɔbrik fayn fayn wan na di men tin dɛn we yu fɔ du fɔ mek yu kɔntinyu fɔ gɛt dɛn fitin dɛn ya.

Fɔ klin di haydrolik push fitin dɛn, yu fɔ pul ɛni dɔti, dɔti, ɔ dɔti tin dɛn we go dɔn gɛda na di fitin say dɛn. Yu kin du dis bay we yu yuz klin klos ɔ brɔsh, wit wan mild ditajɛnt ɔ sɔlvɛnt we di wan we mek am se. I impɔtant fɔ mek shɔ se di tin we dɛn de yuz fɔ klin di tin dɛn we dɛn de yuz fɔ klin di tin dɛn we dɛn de yuz fɔ klin di ples, gri wit di tin we dɛn de yuz fɔ mek di tin fɔ mek i nɔ pwɛl.

Lubrication na impɔtant tin fɔ ridyus frikshɔn ɛn mek shɔ se di haydrolik push fitin dɛn de wok fayn fayn wan. If yu put fayn lɔbrik pan di say dɛn we dɛn fit, dat kin ɛp fɔ mek dɛn nɔ rɔtin ɛn fɔ mek dɛn liv lɔng. I fayn fɔ yuz lɔbrikɛnt dɛn we dɛn mek spɛshal fɔ haydrolik sistem ɛn fala di tin dɛn we di wan we mek am se fɔ yuz am ɔltɛm.

Dɛn nid fɔ chɛk ɔltɛm fɔ mek shɔ se di haydrolik push fitin dɛn de wok fayn fayn wan. Dis min se dɛn fɔ chɛk di fitin dɛn fɔ si if ɛni sayn de we de sho se dɛn lik, dɛn dɔn pwɛl, ɔ dɛn dɔn west. Ɛni fitin we sho sayn fɔ se i dɔn pwɛl, dɛn fɔ chenj am wantɛm wantɛm fɔ mek di sistɛm nɔ pwɛl. Inspekshɔn ɔltɛm kin ɛp bak fɔ no ɛni prɔblɛm we kin apin na di sistɛm ɛn fɔ adrɛs am bifo dɛn go bifo to big prɔblɛm.

C. Limiteshɔn ɛn Kɔnstrakshɔn

Pan ɔl we haydrolik push fitin dɛn de gi bɔku bɛnifit, dɛn gɛt sɔm tin dɛn we dɛn nɔ ebul fɔ du ɛn sɔm tin dɛn we dɛn fɔ tink bɔt. Dɛn fitin ya nɔ go fayn fɔ ɔl di aplikeshɔn dɛn ɛn fɔ ɔndastand wetin dɛn nɔ ebul fɔ du rili impɔtant fɔ mek yu disayd fɔ du sɔntin we yu no.

Wan limiteshɔn fɔ haydrolik push fitin dɛn na we dɛn fit fɔ ay-prɛshɔn aplikeshɔn dɛn. Insay di sityueshɔn dɛn we di haydrolik sistɛm de wok pan rili ay prɛshɔn, tradishɔnal fitin dɛn kin fayn mɔ bikɔs dɛn ebul fɔ handle ay prɛshɔn rɛytin. I impɔtant fɔ asɛs di prɛshɔn we di sistɛm nid ɛn kɔnsul wit masta sabi pipul dɛn fɔ no di kayn fitin we fit pas ɔl.

Semweso, di tɛmpracha limiteshɔn kin afɛkt bak di we aw di haydrolik push fitin dɛn de wok. If di ples wam pasmak, dat kin mek di fitin dɛn big ɔ kɔntrakt, ɛn dis kin mek dɛn lik ɔ nɔ wok. I impɔtant fɔ tink bɔt di tɛmpracha rɛnj fɔ di haydrolik sistɛm ɛn pik fitin dɛn we go ebul fɔ bia wit di tɛmpracha we dɛn de ɛkspɛkt.

Insay sɔm aplikeshɔn dɛn usay di sistɛm nid fɔ diskɔnekshɔn ɛn kɔnɛkt bak bɔku tɛm, tradishɔnal fitin dɛn wit kɔnɛkshɔn we gɛt trɛd kin bi mɔ prɛktikal. Dɛn mek haydrolik push fitin dɛn fɔ mek dɛn ebul fɔ instɔl dɛn kwik ɛn izi, bɔt dɛn nɔ kin fayn fɔ yuz dɛn we nid fɔ chenj ɔ ajɔst ɔltɛm.

Dɔn

Fɔ dɔn, haydrolik push fitin dɛn impɔtant na haydrolik sistem fɔ kɔnɛkshɔn we pɔsin kin abop pan ɛn we nɔ gɛt lik. Dɛn de gi kwik ɛn izi instɔleshɔn, difrɛn kayn fɔ mek yu ebul fɔ chenj, ɛn fɔ mek yu ebul fɔ disayn ɛn mentenɛns di sistem fayn fayn wan. Dɛn fitin dɛn ya de gi bɛnifit dɛn lɛk aw i izi fɔ instɔl, kɔnɛkshɔn we nɔ de lik, aw fɔ wok fayn, aw pɔsin kin abop pan, ɛn aw i nɔ go tek bɔku mɔni. Dɛn kin yuz bɔku tin dɛn, dɛn kin ebul fɔ chenj, ɛn dɛn kin wok fɔ difrɛn aplikeshɔn dɛn, wit sef ficha dɛn we de mek shɔ se ɔl di sistɛm dɛn kin abop pan. Di rayt sayz, pik, mentenɛns, ɛn ɔndastand di limiteshɔn impɔtant we yu de yuz haydrolik push fitin fɔ mek shɔ se yu de wok sef ɛn efyushɔn.

Kwɛstyɔn dɛn we Dɛn kin Aks Bɔku tɛm

K: Wetin na di bɛnifit dɛn we yu kin gɛt we yu yuz haydrolik push fitin?

A: Haydrolik push fitin dɛn de gi bɔku bɛnifit dɛn, lɛk fɔ instɔl am kwik ɛn izi wan we yu nɔ nid spɛshal tul dɛn. Dɛn kin gi kɔnɛkshɔn bak we sikrit ɛn we pɔsin kin abop pan, we kin mek di risk fɔ lik nɔ bɔku. Apat frɔm dat, haydrolik push fitin dɛn kin mek i izi fɔ diskɔnekt ɛn kɔnɛkt bak, we kin mek i izi fɔ mek dɛn mentenɛns ɛn ripɛnt.

K: Aw yu kin kɔmpia haydrolik push fitin dɛn wit tradishɔnal fitin dɛn?

A: We yu kɔmpia am wit tradishɔnal fitin dɛn, haydrolik push fitin dɛn de gi fast ɛn simpul instɔleshɔn. Dɛn kin mek dɛn nɔ nid fɔ trɛd ɔ sɔlda, ɛn dis kin mek dɛn nɔ spɛn bɔku tɛm ɛn trɛnk. Haydrolik push fitin dɛn de gi bak wan kɔnɛkshɔn we sikrit ɛn we nɔ de lik, we de ridyus di risk fɔ mek di sistɛm nɔ wok. Apat frɔm dat, i kin izi fɔ pul dɛn ɛn yuz dɛn bak, ɛn dis kin mek dɛn ebul fɔ chenj ɛn i izi fɔ yuz.

K: Yu kin yuz haydrolik push fitin wit difrɛn kayn tub?

A: Yɛs, dɛn mek di haydrolik push fitin dɛn fɔ mek dɛn go ebul fɔ yuz difrɛn kayn tub dɛn, lɛk kɔpa, stenlɛs stiɛl, ɛn plastic. Dis versatility alaw fɔ yuz dɛn na bɔku bɔku aplikeshɔn ɛn industri. I impɔtant fɔ mek shɔ se di tubing ɛn fitin saiz dɛn mach fɔ mek shɔ se kɔnɛkshɔn fayn ɛn sikrit.

K: Yu tink se i izi fɔ instɔl haydrolik push fitin dɛn we yu nɔ gɛt spɛshal tul dɛn?

A: Yɛs, dɛn mek haydrolik push fitin dɛn fɔ mek i izi fɔ instɔl ɛn nɔ nid spɛshal tul dɛn. Dɛn kin gɛt wan simpul we fɔ push fɔ kɔnɛkt, we kin mek dɛn ebul fɔ gɛda kwik ɛn nɔ gɛt prɔblɛm. Dis de mek haydrolik push fitin dɛn fayn fɔ ɔl tu di prɔfɛshɔnal plamba dɛn ɛn di wan dɛn we lɛk fɔ du DIY, we de sev tɛm ɛn tray we dɛn de instɔl.

K: Yu tink se haydrolik push fitin dɛn nid fɔ mentenɛns ɔltɛm?

A: Haydrolik push fitin dɛn jɔs nɔ nid fɔ mentenɛns ɔltɛm. We dɛn dɔn instɔl dɛn fayn, dɛn kin gi kɔnɛkshɔn we pɔsin kin abop pan ɛn we nɔ kin lik. Bɔt i impɔtant fɔ chɛk di fitin dɛn wan wan tɛm fɔ si if ɛni sayn de we de sho se dɛn dɔn pwɛl ɔ dɛn dɔn west. If dɛn si ɛni prɔblɛm, dɛn fɔ chenj di fitin dɛn fɔ mek shɔ se dɛn kɔntinyu fɔ wok ɛn sef.

K: Yu tink se dɛn kin yuz haydrolik push fitin dɛn bak?

A: Yes, haydrolik push fitin dɛn kin yuz bak. I izi fɔ pul dɛn ɛn kɔnɛkt dɛn bak ɛn nɔ pwɛl di fitin ɔ di tub. Dis kin mek i izi fɔ mek dɛn mentenɛns, ripɛnt, ɔ chenj dɛn ɛn dɛn nɔ nid fɔ put ɔda fitin dɛn. Bɔt i impɔtant fɔ mek shɔ se di fitin dɛn de fayn ɛn klin dɛn fayn bifo yu yuz dɛn bak fɔ mek dɛn kɔntinyu fɔ wok fayn.

K: Us sef ficha dɛn we haydrolik push fitin dɛn de gi?

A: Haydrolik push fitin dɛn de gi sɔm sef ficha dɛn fɔ mek shɔ se yu gɛt kɔnɛkshɔn we sikrit ɛn we pɔsin kin abop pan. Dɛn kin inklud wan lɔk mɛkanism we de mek aksidɛntal diskɔnekshɔn nɔ de, we de ridyus di risk fɔ lik ɔ fɔ mek di sistɛm nɔ wok. Sɔm fitin dɛn gɛt bak indikɛtɔ dɛn we pɔsin kin si ɔ we pɔsin kin yɛri fɔ klik fɔ kɔnfirm se dɛn dɔn gɛda di rayt we. Apat frɔm dat, dɛn mek di haydrolik push fitin dɛn fɔ bia wit ay prɛshɔn ɛn tɛmpracha, we go mek shɔ se dɛn de wok sef wan na say dɛn we tin tranga.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu