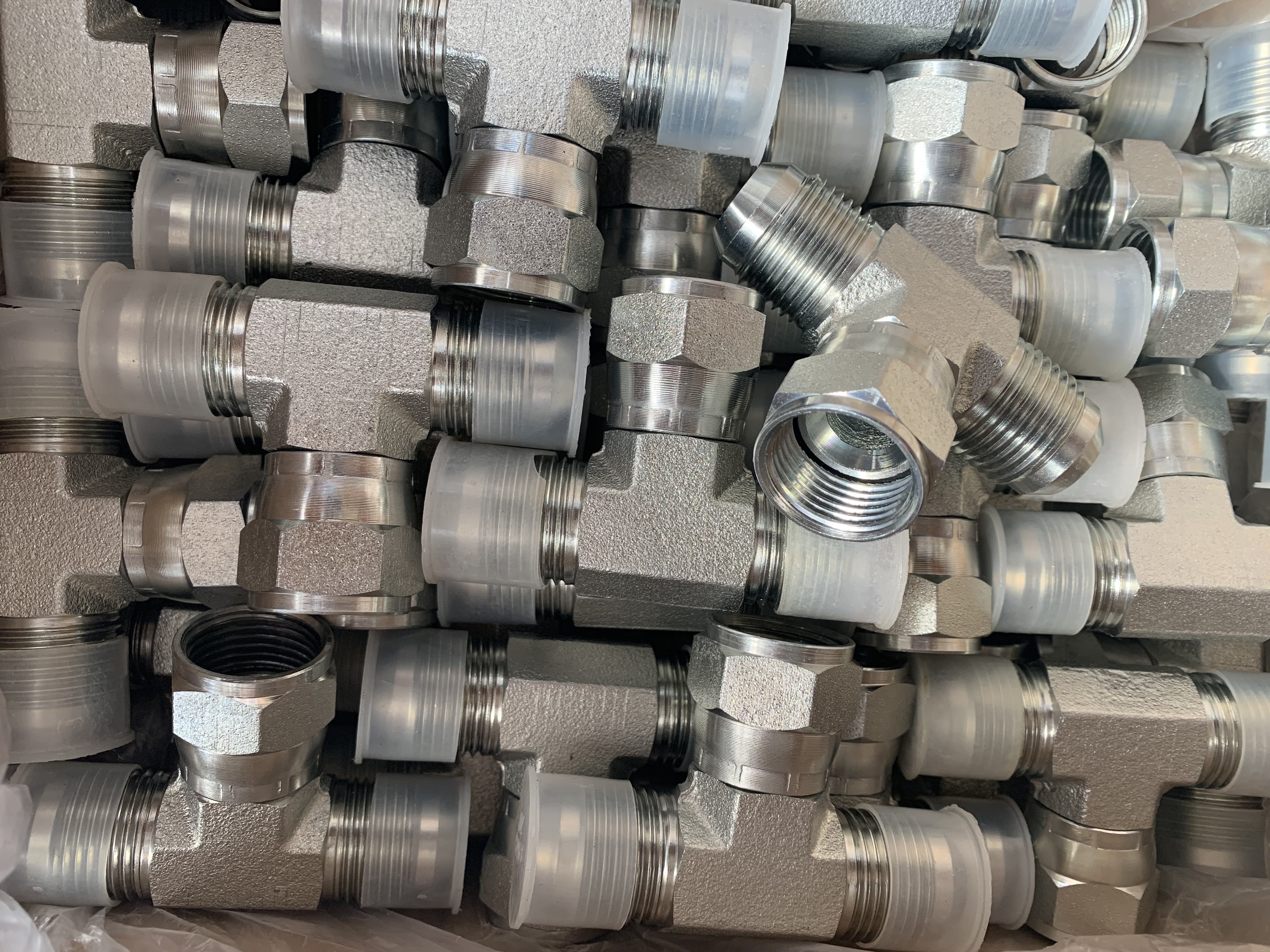

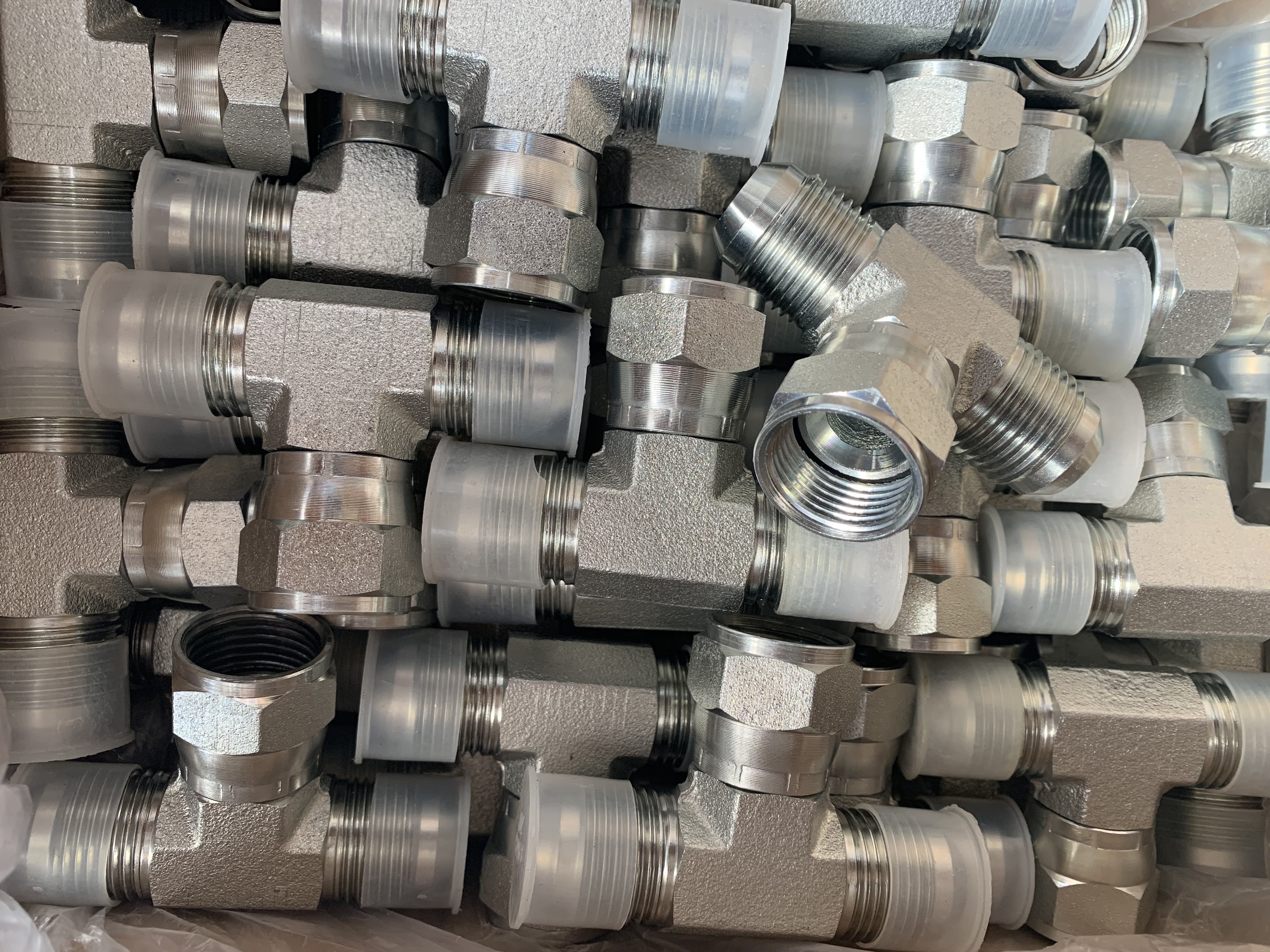

Hydraulic fittings play a crucial role in various industries, ensuring the smooth and efficient operation of hydraulic systems. These fittings are essential components that connect different parts of a hydraulic system, allowing for the transfer of fluids and the transmission of power. Understanding the significance of hydraulic fittings is vital for anyone involved in industries such as manufacturing, construction, or transportation, where hydraulic systems are extensively used.

In the field of hydraulic fittings, it is essential to have a solid understanding of the various acronyms used to describe different types of fittings. One such acronym that holds particular importance is JIC, which stands for Joint Industry Council. JIC fittings are widely used in hydraulic systems due to their reliability and versatility. However, deciphering and comprehending these acronyms can be a challenge for those new to the industry or unfamiliar with the terminology.

In this article, we will delve into the world of hydraulic fittings, exploring their significance in different industries and shedding light on the importance of understanding acronyms, specifically focusing on JIC. By gaining a comprehensive understanding of hydraulic fittings and acronyms, professionals can make informed decisions when selecting the right fittings for their hydraulic systems, ensuring optimal performance and reliability. So, let's dive in and unravel the complexities of hydraulic fittings and the significance of acronyms in this dynamic field.

What is JIC?

The full form of JIC (Joint Industry Council) and its relevance in the hydraulic fittings domain.

JIC, which stands for Joint Industry Council, is a widely recognized and respected standard in the hydraulic fittings domain. The Joint Industry Council was established to bring together various industry experts and manufacturers to develop a common set of standards for hydraulic fittings. This standardization ensures compatibility and interchangeability between different manufacturers' products, making it easier for users to select and install hydraulic fittings without any compatibility issues.

The relevance of JIC in the hydraulic fittings domain cannot be overstated. With the use of JIC fittings, hydraulic systems can operate smoothly and efficiently. These fittings are designed to provide a secure and leak-free connection between various components of a hydraulic system, such as hoses, pipes, and valves. The JIC standard ensures that these fittings are manufactured to precise specifications, guaranteeing their reliability and performance.

The history and origin of JIC.

The history of JIC dates back to the early 20th century when the need for standardization in the hydraulic fittings industry became apparent. Prior to the establishment of JIC, there was a lack of uniformity in the design and dimensions of hydraulic fittings, which often resulted in compatibility issues and increased costs for users. Recognizing this problem, industry leaders came together to form the Joint Industry Council in the 1930s.

The Joint Industry Council aimed to develop a common set of standards for hydraulic fittings that would be accepted and adopted by manufacturers worldwide. Through extensive research and collaboration, the JIC committee established a comprehensive set of specifications for hydraulic fittings, including thread sizes, angles, and tolerances. These standards were designed to ensure that fittings from different manufacturers could be easily interchanged without compromising performance or safety.

The standardization and widespread adoption of JIC fittings.

Since its inception, JIC has gained widespread acceptance and adoption in the hydraulic fittings industry. Manufacturers around the world have embraced the JIC standard, recognizing its benefits in terms of compatibility, reliability, and ease of use. The standardization of JIC fittings has greatly simplified the selection and installation process for hydraulic systems, saving both time and money for users.

One of the key advantages of JIC fittings is their interchangeability. Thanks to the standardized dimensions and specifications, JIC fittings from different manufacturers can be easily interchanged without the need for additional modifications or adjustments. This interchangeability not only simplifies the installation process but also allows for greater flexibility in system design and maintenance.

Another significant benefit of JIC fittings is their leak-free performance. The JIC standard ensures that fittings are manufactured to tight tolerances, minimizing the risk of leaks and ensuring the integrity of the hydraulic system. This reliability is crucial in applications where even a small leak can lead to significant downtime, loss of productivity, and potential safety hazards.

Understanding JIC Fittings

A detailed explanation of JIC fittings, their design, and construction

JIC fittings, also known as Joint Industry Council fittings, are a type of hydraulic fitting commonly used in various industries. These fittings are designed to provide a reliable and leak-free connection between hydraulic components, ensuring the efficient operation of hydraulic systems.

JIC fittings are renowned for their robust construction and exceptional performance. They consist of three main components: the fitting body, the sleeve, and the nut. The fitting body is typically made of high-quality steel or stainless steel, which ensures its durability and resistance to corrosion. The sleeve, also known as the ferrule, is a small cylindrical piece that is placed over the end of the hydraulic hose. It acts as a compression seal, preventing any leakage from occurring. The nut is used to secure the fitting by tightening it onto the fitting body, compressing the sleeve and creating a tight seal.

One of the key design features of JIC fittings is their 37-degree flare angle. This specific angle allows for a reliable and secure connection between the fitting and the hydraulic component. The flare angle ensures that the fitting can withstand high pressure and vibration without loosening or leaking. Additionally, the 37-degree flare angle provides a larger sealing surface, resulting in improved sealing capabilities and increased resistance to leakage.

The key features and components of JIC fittings

JIC fittings offer several key features that make them a preferred choice in hydraulic systems. Firstly, their design allows for easy installation and removal, making them highly convenient for maintenance and repair purposes. The use of a sleeve and nut system simplifies the assembly process, reducing the time and effort required to connect hydraulic components.

Another important feature of JIC fittings is their versatility. These fittings are available in a wide range of sizes and configurations, allowing them to be used in various hydraulic applications. Whether it is a high-pressure hydraulic system or a low-pressure one, JIC fittings can accommodate different requirements. This versatility ensures compatibility and interchangeability, making JIC fittings a cost-effective solution for hydraulic system design and implementation.

In addition to their design features, JIC fittings offer several components that contribute to their overall functionality. One such component is the O-ring, which is often used in JIC fittings to provide an additional layer of sealing. The O-ring is placed between the fitting body and the nut, creating a tight seal that prevents any leakage. This feature is particularly important in applications where the hydraulic system operates under high pressure or experiences frequent vibrations.

The advantages and benefits of using JIC fittings in hydraulic systems

The use of JIC fittings in hydraulic systems offers numerous advantages and benefits. Firstly, their reliable and leak-free connection ensures the integrity of the hydraulic system. This is crucial in preventing any fluid leakage, which can lead to system inefficiencies, component failures, and potential safety hazards. JIC fittings provide a secure connection that can withstand high pressures, ensuring the smooth and efficient operation of the hydraulic system.

Another advantage of JIC fittings is their compatibility with various types of hydraulic hoses. These fittings can be used with both rubber and thermoplastic hoses, allowing for greater flexibility in system design. This compatibility eliminates the need for specialized fittings for different hose materials, simplifying the procurement process and reducing inventory costs.

Furthermore, JIC fittings are known for their durability and long service life. The use of high-quality materials in their construction ensures their resistance to corrosion, abrasion, and wear. This durability translates into cost savings for businesses, as the need for frequent replacements or repairs is minimized.

JIC Fittings vs. Other Fitting Types

Compare JIC fittings with other commonly used fitting types

JIC fittings, also known as Joint Industry Council fittings, are widely used in hydraulic systems. These fittings provide a reliable connection between hoses, pipes, and other components. However, it is essential to understand how JIC fittings compare to other commonly used fitting types, such as NPT (National Pipe Thread) and ORFS (O-Ring Face Seal), to make informed decisions regarding their usage in specific applications.

Design Differences

JIC fittings feature a 37-degree flare seating surface, which provides a metal-to-metal seal. This design ensures a tight and leak-free connection, making JIC fittings suitable for high-pressure applications. On the other hand, NPT fittings have a tapered thread design that relies on the deformation of the threads to create a seal. While NPT fittings are widely used in low-pressure applications, they may not be as reliable as JIC fittings when it comes to high-pressure systems.

ORFS fittings, on the other hand, utilize an O-ring and a flat face to create a seal. This design offers excellent sealing capabilities and is commonly used in applications where high pressure and vibration resistance are crucial. However, it is worth noting that ORFS fittings may require additional components, such as O-rings, to ensure proper sealing, unlike JIC fittings, which provide a complete sealing solution.

Sealing Mechanism

The sealing mechanism of JIC fittings relies on the metal-to-metal contact between the flared fitting and the flared tubing. This design ensures a reliable and durable seal that can withstand high pressures. Additionally, JIC fittings provide excellent resistance to vibration, making them suitable for applications where mechanical stress is a concern.

NPT fittings, on the other hand, rely on the deformation of the tapered threads to create a seal. While this design is effective in low-pressure applications, it may not be as reliable as the metal-to-metal seal provided by JIC fittings. NPT fittings are also more prone to leakage due to the potential for thread damage or misalignment during installation.

ORFS fittings utilize an O-ring and a flat face to create a seal. This design offers excellent sealing capabilities, especially in high-pressure applications. The O-ring provides a reliable seal, while the flat face ensures proper alignment and contact between the fitting and the mating surface. However, it is important to ensure that the O-ring is properly installed and in good condition to maintain the sealing integrity of ORFS fittings.

Applications and Usage

JIC fittings are commonly used in hydraulic systems, particularly in applications where high pressure and vibration resistance are critical. Their metal-to-metal seal and robust design make them suitable for a wide range of industries, including aerospace, automotive, and industrial manufacturing. JIC fittings are also compatible with a variety of fluids, including hydraulic oils, fuels, and coolants.

NPT fittings are widely used in plumbing and low-pressure applications. Their tapered thread design allows for easy installation and disassembly, making them suitable for applications that require frequent maintenance or repairs. However, NPT fittings may not be suitable for high-pressure systems or applications where vibration resistance is crucial.

ORFS fittings are commonly used in hydraulic systems that require high pressure and vibration resistance. Their sealing mechanism and flat face design make them ideal for applications in construction, agriculture, and mining industries. However, it is important to consider the additional components, such as O-rings, that may be required for proper installation and sealing.

Pros and Cons

JIC fittings offer several advantages, including a reliable metal-to-metal seal, resistance to vibration, and compatibility with various fluids. However, they may be more expensive compared to NPT fittings and require proper flaring tools for installation. Additionally, JIC fittings may not be as readily available as NPT fittings in certain regions.

NPT fittings are widely available, cost-effective, and easy to install. They are suitable for low-pressure applications and offer convenience in terms of maintenance and repairs. However, NPT fittings may not provide the same level of sealing integrity as JIC fittings, and their tapered thread design may limit their usage in high-pressure systems.

ORFS fittings provide excellent sealing capabilities, high-pressure resistance, and vibration resistance. They are commonly used in demanding applications where reliability is crucial. However, the additional components required for installation and sealing may increase the overall cost and complexity of the system.

Common Applications of JIC Fittings

The various industries and sectors where JIC fittings are extensively used.

JIC fittings, also known as Joint Industry Council fittings, are widely used in various industries and sectors due to their exceptional performance and reliability. These fittings are specifically designed to provide a secure and leak-free connection in hydraulic systems, machinery, and equipment. One of the key reasons for their popularity is their compatibility with different types of fluids, including hydraulic oils, water, and chemicals. This makes JIC fittings suitable for a wide range of applications across different industries.

In the automotive industry, JIC fittings are commonly used in brake systems, power steering systems, and transmission systems. The high-pressure hydraulic systems in these vehicles require fittings that can withstand extreme conditions and provide a tight seal. JIC fittings, with their robust construction and precise threading, ensure a reliable connection, minimizing the risk of leakage or failure. Additionally, their ease of installation and maintenance makes them a preferred choice for automotive manufacturers and repair shops.

Another industry where JIC fittings find extensive use is the aerospace sector. Aircraft hydraulic systems operate under extremely demanding conditions, including high pressure, temperature variations, and vibrations. JIC fittings, with their exceptional durability and resistance to corrosion, can withstand these harsh environments. They are commonly used in hydraulic lines, fuel systems, and landing gear assemblies, ensuring the safe and efficient operation of aircraft. The precision and reliability of JIC fittings are crucial in this industry, as any failure can have catastrophic consequences.

Specific examples of applications in hydraulic systems, machinery, and equipment.

JIC fittings are widely employed in hydraulic systems across various industries. In industrial machinery, such as hydraulic presses and injection molding machines, JIC fittings are used to connect hydraulic lines and control the flow of hydraulic fluid. These fittings ensure a leak-free connection, preventing any loss of pressure and maintaining the efficiency of the machinery. Moreover, JIC fittings are often utilized in construction equipment, such as excavators and cranes, to enable smooth and reliable operation of hydraulic functions.

In the oil and gas industry, JIC fittings play a crucial role in connecting hydraulic hoses and pipes in drilling rigs, wellheads, and production equipment. The rugged nature of this industry demands fittings that can withstand high pressures and harsh environmental conditions. JIC fittings, with their robust design and superior sealing capabilities, provide a reliable solution for these applications. Whether it is offshore drilling or onshore extraction, JIC fittings ensure the integrity of hydraulic systems, minimizing downtime and enhancing productivity.

The reliability and versatility of JIC fittings in demanding environments.

JIC fittings have gained a reputation for their reliability and versatility, making them suitable for use in demanding environments. These fittings are able to withstand high pressures, extreme temperatures, and corrosive substances, ensuring a long service life even in challenging conditions. Whether it is in heavy machinery, industrial equipment, or critical infrastructure, JIC fittings provide a dependable connection that can be trusted.

One of the key advantages of JIC fittings is their ease of installation and maintenance. The standardized design and precise threading make them easy to assemble and disassemble, reducing downtime during repairs or replacements. This is particularly beneficial in industries where equipment uptime is crucial, such as manufacturing plants or power generation facilities. The versatility of JIC fittings allows for quick and efficient modifications or upgrades to hydraulic systems, minimizing disruption to operations.

Proper Installation and Maintenance of JIC Fittings

The correct installation procedures for JIC fittings, including torque specifications and thread engagement.

When it comes to the proper installation of JIC fittings, there are a few key procedures that should be followed to ensure a secure and leak-free connection. Firstly, it is important to clean both the male and female threads of the fitting before installation. This can be done using a lint-free cloth or a wire brush to remove any dirt or debris that may hinder proper engagement.

Next, it is crucial to apply the appropriate amount of torque to the fitting during installation. Over-tightening can lead to damaged threads or even cracking of the fitting, while under-tightening can result in a loose connection and potential leaks. To determine the correct torque specifications, it is recommended to consult the manufacturer's guidelines or industry standards.

Thread engagement is another critical aspect of JIC fitting installation. The male and female threads should be fully engaged to ensure a tight seal. This can be achieved by tightening the fitting until it is snug, and then using a wrench to make an additional 1/4 to 1/2 turn. This will provide the necessary thread engagement for a secure connection.

The importance of proper maintenance and inspection to ensure leak-free connections.

Proper maintenance and regular inspection of JIC fittings are essential to ensure leak-free connections and prevent any potential issues. One of the most important aspects of maintenance is checking for any signs of leakage. This can be done by visually inspecting the fittings for any visible leaks or drips. Additionally, it is recommended to use a leak detection solution or a soapy water mixture to identify any small leaks that may not be immediately visible.

Regular inspection of JIC fittings also involves checking for any signs of wear or damage. This includes inspecting the threads for any signs of stripping or cross-threading, as well as examining the fitting body for any cracks or deformations. Any fittings that show signs of wear or damage should be replaced immediately to prevent leaks or potential failures.

In addition to visual inspection, it is important to perform regular torque checks on JIC fittings. Over time, the torque applied during installation may loosen due to vibration or other factors. By periodically checking and retightening the fittings to the specified torque, the risk of leaks can be significantly reduced.

Tips and best practices for troubleshooting and addressing common issues with JIC fittings.

While JIC fittings are known for their reliability and durability, there are some common issues that may arise during their use. Understanding these issues and knowing how to troubleshoot them can help ensure the proper functioning of JIC fittings.

One common issue with JIC fittings is thread galling. This occurs when the threads of the fitting seize or lock together during installation, making it difficult to tighten or loosen the fitting. To prevent thread galling, it is recommended to apply an anti-seize compound or lubricant to the threads before installation. This will help reduce friction and allow for smooth engagement of the threads.

Another common issue is over-tightening of JIC fittings. As mentioned earlier, over-tightening can lead to damaged threads or cracked fittings. To avoid this, it is important to follow the recommended torque specifications provided by the manufacturer. Using a torque wrench can help ensure that the fittings are tightened to the correct specification.

In some cases, leaks may occur even with proper installation and maintenance. When troubleshooting leaks, it is important to check the integrity of the O-ring or seal inside the fitting. If the O-ring is damaged or worn out, it should be replaced. Additionally, checking the alignment of the fitting and ensuring that it is properly seated can help prevent leaks.

Conclusion

the article highlights the significance of JIC (Joint Industry Council) fittings in the hydraulic industry. These fittings have revolutionized the industry by providing standardized specifications for manufacturers worldwide, simplifying the selection and installation process. JIC fittings are known for their reliability, performance, and leak-free design, making them widely adopted in various industries. They offer advantages such as compatibility, durability, and leak-free connections, making them a preferred choice. Understanding the differences between JIC fittings, NPT fittings, and ORFS fittings is crucial for selecting the appropriate fitting type for specific hydraulic applications. JIC fittings find widespread use in different sectors due to their reliability, versatility, and compatibility with different fluids. Proper installation and maintenance of JIC fittings are crucial for achieving leak-free connections and optimal performance. By adhering to best practices, the longevity and reliability of JIC fittings can be maximized.

Frequently Asked Questions

Q: What are the advantages of JIC fittings over other fitting types?

A: JIC fittings have several advantages over other fitting types. Firstly, they provide a reliable and leak-free connection, ensuring the integrity of the hydraulic system. Secondly, JIC fittings have a wide range of sizes and configurations, making them versatile and compatible with various applications. Lastly, JIC fittings are easy to assemble and disassemble, allowing for quick maintenance and repairs.

Q: Can JIC fittings be used in high-pressure hydraulic systems?

A: Yes, JIC fittings are suitable for use in high-pressure hydraulic systems. They are designed to withstand high pressures and provide a secure connection. However, it is essential to ensure that the JIC fittings used are rated for the specific pressure requirements of the system to ensure safety and optimal performance.

Q: How do I identify the thread size of a JIC fitting?

A: To identify the thread size of a JIC fitting, you can use a thread gauge or a caliper. Measure the outside diameter and count the number of threads per inch. For example, a fitting with an outside diameter of 0.5 inches and 20 threads per inch would be identified as a 1/2-20 JIC fitting.

Q: Are JIC fittings compatible with different types of hydraulic fluids?

A: Yes, JIC fittings are compatible with various types of hydraulic fluids. They are commonly used with hydraulic oils, water-glycol, and synthetic fluids. However, it is essential to consider the compatibility of the specific material used in the JIC fitting with the hydraulic fluid to ensure long-term compatibility and prevent any degradation or leakage.

Q: Can JIC fittings be reused or should they be replaced after disassembly?

A: JIC fittings can be reused, but it is recommended to inspect them carefully before reuse. Check for any signs of damage, wear, or deformation that may affect the fitting's performance or integrity. If any issues are found, it is advisable to replace the fitting to ensure a reliable and leak-free connection.

Q: What are the common thread sizes available for JIC fittings?

A: The common thread sizes available for JIC fittings range from 1/8 inch to 2 inches. Some of the standard sizes include 1/4-18, 3/8-18, 1/2-14, 3/4-14, 1-11.5, and 1-1/4-11.5. These sizes cover a wide range of applications and are readily available in the market.

Q: Are JIC fittings interchangeable with metric fittings?

A: JIC fittings and metric fittings are not directly interchangeable due to the difference in thread sizes and configurations. JIC fittings use imperial measurements, while metric fittings use metric measurements. However, adapters or fittings with dual threads are available to facilitate the connection between JIC and metric systems, allowing for compatibility between the two fitting types.