Wake wazibuza yini ngezinhlobo ezahlukene ze-hydraulic O-ring fittings nezinjongo zazo? Ngiyazi ukuthi kungadida kanjani ngezinketho eziningi laphaya. Kungakho ngilapha - ukuzokuqondisa emhlabeni oyinkimbinkimbi wokufakwa kwe-hydraulic, ikakhulukazi okugxilwe ku-O-ring face seal (ORFS) kanye nokufakwa kwe-O-ring boss (ORB). Nakuba kokubili lokhu kufakwa kubalulekile ekudaleni uphawu oluvikelekile ezinhlelweni ze-hydraulic, ngayinye ineqhaza layo nezinzuzo ezihlukile. Namuhla, sizokwembula imfihlakalo ngemuva kwalezi zinhlobo ezimbili ezidumile. Angase azwakale njengamagama obuchwepheshe ekuqaleni, kodwa ngiyakuqinisekisa, ukuwaqonda kuyisihluthulelo sokuxhuma okungavuzi kwe-hydraulic. Ngakho-ke, hamba nami njengoba sihlola ama-nuances we-ORFS kanye nokufakwa kwe-ORB futhi uthole ukuthi kungani kungase kufane kahle nezidingo zakho zesistimu ye-hydraulic. Asingene kulokhu ndawonye futhi senze umqondo womhlaba wokufakwa kwe-hydraulic!

Ukuqonda ukufakwa kwe-O-Ring Face Seal (ORFS)

Incazelo kanye Nokwakheka Kokufakwayo kwe-ORFS

![I-1F ORFS I-O-RING YESIlisa i-orfs i-hydraulic fitting]()

I-1F ORFS I-O-RING YESIlisa i-orfs i-hydraulic fitting

Ukufakwa kwe-O-Ring Face Seal (ORFS) kuwuhlobo lokufakwa kwe-hydraulic . Zinendawo eyisicaba yokuvala kanye ne -O-ring yerabha yokwenziwa ebekwe emseleni. Uma uxhuma ukufaka i-ORFS, i- O-ring iyaminyanisa , idale uphawu oluqinile kakhulu. Yingakho i-ORFS yaziwa njengendlela uphawu okungavuzi . yokuvala

Amazinga Nemininingwane: SAE J1453 kanye ne-ISO 8434-3

Ukufakwa kwe-ORFS kufanele kuhlangabezane nezindinganiso ezithile. I -SAE J1453 kanye ne -ISO 8434-3 yimithetho elandelwa yilokhu kufakwa. Lawa mazinga asiza ukwenza isiqiniseko sokuthi ukufakwa kwe-ORFS kusebenza kahle kumasistimu asebenza ngamanzi . Bakhuluma ngokuthi izinto ezifakwayo kufanele zenziwe kanjani, kufanele zibe usayizi onjani, nokuthi kufanele zihlolwe kanjani.

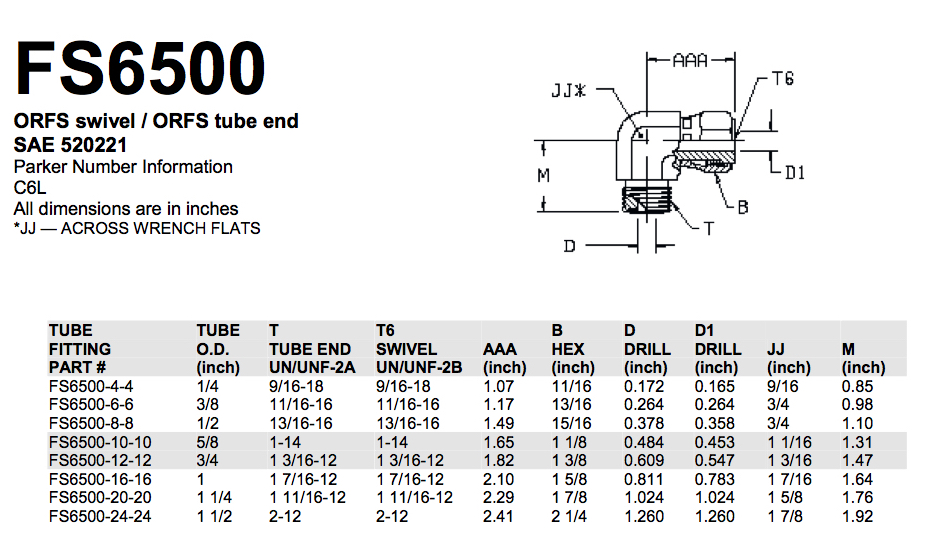

![FS6500 ORFS swivel / ORFS tube end SAE 520221 elbow connector I-FS6500 ORFS swivel / ORFS isiphetho seshubhu SAE 520221 isixhumi sendololwane]()

I-FS6500 ORFS swivel / ORFS isiphetho seshubhu SAE 520221 isixhumi sendololwane

Izicelo kanye Nezinzuzo Zokufakwa kwe-ORFS kumaHydraulic Systems

Ukufakwa kwe-ORFS kuhle kumasistimu asebenza ngogesi ngoba awavuzi. Asetshenziswa ezinhlelweni zokucindezela okuphezulu njengama- hydraulic excavators, ama-loaders, ama-forklift, nogandaganda . Enye into enkulu ukuthi bangakwazi ukubhekana nezingcindezi zokusebenza ngaphandle kokudala amaphuzu okuvuza.

![ORFS tube ends SAE 520432 couplings and tee Ishubhu ye-ORFS iphetha ama-couplings we-SAE 520432 kanye ne-tee]()

Ishubhu ye-ORFS iphetha ama-couplings we-SAE 520432 kanye ne-tee

Ukucatshangelwa kosayizi nokuhambisana kokufakwa kwe-ORFS

Uma ukhetha ukufaka kwe-ORFS, usayizi ubalulekile. Kufanele uqiniseke ukuthi ilingana neshubhu le-hydraulic noma ipayipi lepayipi osebenza nalo. Ishadi likasayizi wophawu lobuso bendandatho ye-SAE O-ring likusiza ukuthi uthole usayizi ohlukile we-O-ring womsebenzi wakho. Kubalulekile ukufanisa kowesilisa nowesifazane ukuxhumana ngendlela efanele. Lokhu kuqinisekisa ukuthi izindawo zokuvala zithinta indlela efanele kanye nezigxivizo ze-O-ring ngendlela efanele.

Ukufakwa kwe-ORFS kuza ngezinto ezahlukene. Ungawathola ku -carbon, nickel-plated carbon , kanye nensimbi engagqwali . Ama-O-rings enziwe ngezinto ezifana ne -Buna-n ne -Viton . Lokhu kusho ukuthi ungazisebenzisa ezinhlelweni eziningi zezimboni.

Ukufakwa kwe -O-Ring Face Seal kuyisinqumo esihlakaniphile samasistimu asebenza ngamanzi . Balandela amazinga e -SAE J1453 kanye ne -ISO 8434-3 . Asebenza kahle ngoba awavuzi futhi ayakwazi ukumelana nomfutho ophakeme . Qiniseka ukuthi uhlola osayizi ngokucophelela usebenzisa ishadi losayizi wophawu lobuso bendandatho ye-SAE O-ring . Lokhu kuzokusiza ukuthi uthole okulingana kahle kwama-adaptha akho asebenza ngaphansi komhlaba kanye namashubhu . Uma unemibuzo, xhumana nethimba labadayisi . Bangakunikeza imininingwane yokuxhumana nolwazi olwengeziwe.

Ukuhlola O-Ring Boss (ORB) Seal Fittings

Incazelo kanye nesakhiwo se-ORB Fittings

![I-SAE O-ring boss SAE 140257 isixhumi esiluchungechunge sowesilisa]()

I-SAE O-ring boss SAE 140257 isixhumi esiluchungechunge sowesilisa

Ukufakwa kwe-O-ring boss, noma i-ORB ngamafuphi, kuwuhlobo lokufakwa kwe-hydraulic . Banokulingana kowesilisa ngentambo eqondile kanye ne- chamfer emshinini wokubamba i -O-ring . Uxhumano lomuntu wesifazane lunengxenye enentambo nendawo yokuvala eyisicaba . Uma uqinisa izingxenye ezimbili, i -O-ring icindezela , idale uphawu oluqinile.

Amazinga Nemininingwane: ISO 11926-1 kanye ne-SAE J1926-1

Ukufakwa kwe-ORB kulandela izindinganiso ezithile. I-ISO 11926-1 ne -SAE J1926-1 yizona eziyinhloko. Lokhu kusetha imithetho yochungechunge lwe-SAE oluqondile lwe-UNF olusetshenziswa kulokhu kufakwa. Benza isiqiniseko sokuthi konke ukufakwa kwe-ORB kuhlangana kahle kusistimu yamapayipi anamandla awuketshezi.

Ukusetshenziswa Okuvamile Nezinzuzo Zokufakwa Kwe-ORB Embonini

Ukufakwa kwe-ORB kukuyo yonke indawo embonini. Asetshenziswa kuma -hydraulic excavators, ama-loaders, ama-forklift, kanye nogandaganda . Futhi, ungawathola kumavalvu namasistimu egesi kaphethiloli . Izinzuzo? Zilungele izinhlelo zokusebenza ezinomfutho ophezulu futhi zisiza ukuvimbela ukuvuza. Zihlala isikhathi eside futhi zigcina ukusebenza kahle kwesistimu kuphezulu.

Ukulinganisa Ukulinganisa Nokukhethwa Kokufakwayo kwe-ORB

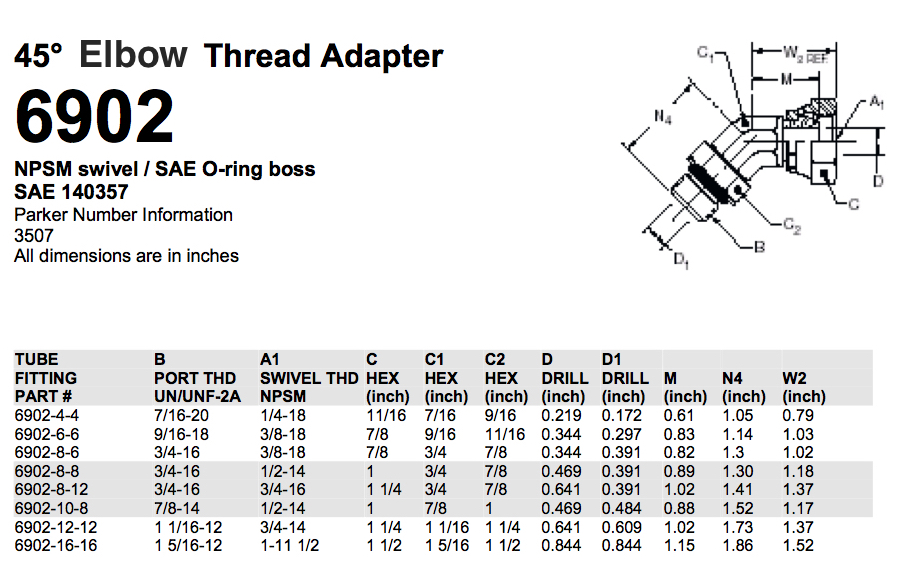

![SAE O-ring boss SAE 140357 45° Elbow Thread Adapter metal pipe connector I-SAE O-ring boss SAE 140357 45° Elbow Thread Adapter isixhumi sepayipi lensimbi]()

I-SAE O-ring boss SAE 140357 45° Elbow Thread Adapter isixhumi sepayipi lensimbi

Lapho ukhetha ukufakwa kwe-ORB okulungile, kufanele ucabange ngosayizi. Ishadi likasayizi wophawu lobuso bendandatho ye-SAE O-ring likusiza ukuthi uthole usayizi ohlukile we-O-ring oyidingayo. Futhi, bheka ukuthi ukufakwa kwenziwa ngani. Izinketho zifaka i-carbon, i-nickel-plated carbon, insimbi engagqwali, i-Buna-n, ne-Viton . Qinisekisa ukuthi i -durometer (ukuqina) ye- O-ring ifana nezidingo zakho.

Uma ukhetha okokufaka kwe-ORB, ufuna uphawu olungavuzi ohlelweni lwakho lwe-hydraulic . Khumbula, izindawo zokuvala kufanele zihlanzeke futhi i -O-ring kufanele ibe usayizi ofanele. Uma udinga usizo, khuluma nethimba labadayisi elaziyo ngama -adaptha ama-hydraulic kanye namashubhu.

Ngamafuphi, ukufakwa kwe-ORB kuyindlela yokuvala esebenzisa ama-O-rings erabha yokwenziwa . Zilungele umfutho ophezulu futhi azivuzi kakhulu. Amazinga e-SAE J1926-1 kanye ne -ISO 11926-1 aqinisekisa ukuthi asebenza kahle ezinhlelweni zezimboni . Uma udinga ukukhetha elilodwa, hlola ishadi likasayizi nokuthi ukufakwa kwenziwa ngani.

Ukuhlaziywa Okuqhathanisayo: O-Ring Face Seal Vs. O-Ring Boss

Ukufana Okubalulekile phakathi kwe-ORFS ne-ORB Fittings

Uma sibheka ukufakwa kwe -O-Ring Face Seal (ORFS) kanye ne-O-Ring Boss (ORB) , kufana nokuqhathanisa abasubathi ababili abaphambili. Bahlukene, kodwa futhi banokuningi abafana ngakho. Ake sihlukanise ukufana kwazo.

I-ORFS ne-ORB zombili zisebenzisa ama-O-rings erabha yokwenziwa ukuvimbela ukuvuza. Lawa ma-O-rings abalulekile ekuqinisekiseni ukuthi uketshezi luhlala luvikelekile ngaphakathi kwamapayipi, ukugwema noma yikuphi ukuchitheka noma ukuvuza.

Kuzo zonke izinhlobo zezinto zokusebenza, kusukela kuma-hydraulic excavators kuya kuma-forklift, uzothola lezi zifakelo zidlala indima ebalulekile. Abalulekile ezinhlelweni zamanzi, alawula ngobuchule umfutho ophakeme ukuze aqinisekise ukuthi yonke into isebenza kahle futhi igcina uketshezi luqukethwe.

Imicu ifana nekhodi eyimfihlo esiza okokufaka ukuthi kuxhumeke futhi kuxhumane. Kokubili i-ORFS ne-ORB zisebenzisa le khodi, ngochungechunge lwe-SAE oluqondile lwe-UNF oluwulimi lwabo okwabelwana ngalo. Yile ndlela izingxenye zesilisa nesifazane zokufakwayo zihlangana futhi zihlale ndawonye.

Ukuhlaziywa Okuqhathanisayo Kwezindlela Zokuvala

Uma sikhuluma ngokufakwa kwe-hydraulic , sivame ukucabanga ngendlela ezigcina ngayo uketshezi lungavuzi. Izinhlobo ezimbili ezijwayelekile i- O-ring face seal (ORFS) kanye ne- O-ring boss (ORB) . Ake singene endleleni ezisebenza ngayo nokuthi zinqwabelana kanjani.

I-Seal Mechanism

Kokubili i-ORFS ne-ORB zinezindlela zazo ezihlukile zokuvala uphawu. Basebenzisa ucezu olubizwa ngokuthi i -O-ring . Lena iluphu yerabha yokwenziwa egijinyiswayo ukuze kuvinjwe uketshezi ukuthi lungaphumi.

I-ORFS Ifinyelela Kanjani Uphawu

I -O-ring face seal fitting inendawo eyisicaba. Uma uyiqinisa, i -O-ring iyacindezelwa phakathi kwale ndawo eyisicaba yokuvala kanye nokuxhumana kowesifazane . Kufana nokucindezela isandla sakho phezu kwesipontshi ukuze ucwiliswe amanzi. Kuyinsimbi kanye ne-O-ring double seal , okusho ukuthi inhle ngempela ekugcineni izinto ziqinile.

I-ORB Ifinyelela Kanjani Uphawu

Ukufakwa kwe-O-ring boss kusebenza ngokuhlukile. Anengxenye enemicu nendawo egobile phansi kwentambo yesilisa . Uma izikulufo zokulinganisa zesilisa zingena embotsheni yochungechunge wesifazane , i -O-ring ebekwe emseleni iyashwibeka. Lokhu kudala uphawu oluqinile eduze kwengxenye enentambo.

Ukuqhathaniswa Kwempumelelo Yokuvala

Kokubili i-ORFS ne-ORB zinhle kakhulu ekumiseni ukuvuza ezinhlelweni zokucindezela okukhulu njengasemgodini wokumba we-hydraulic noma i- forklift . Kodwa, kukhona umehluko.

l I -ORFS ngokuvamile ibhekwa njengengcono ezimweni ezinengcindezi ephezulu . Inendawo eyisicaba yokuvala ekwazi ukuphatha amandla amaningi ngaphandle kokuvuza.

l I-ORB iguquguquka kakhudlwana. Ingangena ezimbobeni ezinosayizi abahlukahlukene, ewusizo ezinhlelweni zemboni.

Kusistimu yamapayipi anamandla awuketshezi , ufuna ukwenza isiqiniseko sokuthi usebenzisa izingxenye ezifanele. I-ORFS ingase ibe ngcono entweni ehlala ingaphansi kwengcindezi enkulu, njengeshubhu elisebenza ngogesi . i-ORB kungase kube indlela yokuya ezingxenyeni ezidinga ukulingana ezindaweni eziningi ezahlukene, njengama -adaptha asebenza ngogesi..

Uma ukhetha phakathi kwe -ORFS ne-ORB , cabanga ngalokho okudingayo. Uma ungenaso isiqiniseko, ungabuza ithimba labadayisi elaziyo ngokuhlanganisa ipayipi le-hydraulic . Bangakusiza ukuthi ukhethe okokufaka uphawu okulungile komsebenzi wakho.

Ukuhlaziya Okuqhathanisayo: Izilinganiso Zokucindezela

Uma sikhuluma ngokufakwa kwe-hydraulic njenge- O-ring face seal (ORFS) kanye ne -O-ring boss (ORB) , sikhuluma ngempela ngendlela abasingatha ngayo ingcindezi. Ake sikuhlephule ukuze kucace kakhulu.

Amandla Okuphatha Ingcindezi ye-ORFS

I -O-ring face seal fitting iyinkanyezi uma kuziwa ekucindezelweni. Yakhelwe ngendlela eyisicaba yokuvala okuhlala kuyo ama-O-rings erabha yokwenziwa . Lokhu kusetha kuhle kakhulu ekubambeni umfutho ophezulu. Eqinisweni, i-ORFS ingathatha ingcindezi efika ku-6000 psi. Lokho kufana nokuba nendlovu encane emi kuwo wonke ama-intshi ayisikwele!

Amandla Okuphatha Ingcindezi ye-ORB

Manje, ake sixoxe ngokufaka uphawu lomphathi we-O-ring . I-ORB isebenzisa ingxenye enentambo kanye nendawo eyenziwe ngomshini we-chamfer lapho kuhlala khona i -O-ring . Ingumdlali oqinile futhi, kodwa ngokuvamile ibamba ingcindezi encane kune-ORFS, cishe ku-3000 kuya ku-5000 psi kuye ngosayizi.

Izimo Lapho Omunye Engase Ancanywe Kunomunye Ngokusekelwe Engcindezini

Ngakho-ke, sikhetha nini omunye kunomunye? Ake ucabange ukuthi une- hydraulic excavator noma i- forklift . Le mishini idinga okokufakwayo okukwazi ukumelana nokucindezela okukhulu ngaphandle kokuvuza. Ezimweni zokucindezela okuphezulu njengalezi, ungahamba ne- O-ring face seal ngoba yakhelwe ukuphatha ingcindezi.

Kodwa akuwona wonke umsebenzi omayelana nengcindezi ephezulu kakhulu. Ngezinye izikhathi, ungase ube nogandaganda noma isilayishi esingasusi imingcele. Kulezi zimo, uphawu lomphathi we-O-ring kungaba ukukhetha okulungile. Isaqinile kodwa ingase ilingane kangcono nedizayini yesistimu nezidingo zengcindezi.

Ukufakwa Nokugcinwa

Uma kuziwa ekufakweni kwe-hydraulic , izinhlobo ezimbili ezidumile i- O-ring face seal (ORFS) kanye ne-O-ring boss (ORB) . Zombili zinezinyathelo zazo zokufaka kanye nokucatshangelwa kokulungisa.

Ukufakwa kwe-ORFS Fittings

1. Hlanza zonke izingxenye ngaphambi kokufaka ukuze ugweme ukungcola.

2. Gcoba i-O-ring ngoketshezi oluhambisanayo ukuze uqinisekise uphawu oluhle.

3. Beka i -O-ring endaweni eyisicaba yokuvala yokulinganisa owesilisa.

4. Qondanisa ukulingana kowesilisa nokuxhumana kowesifazane bese uqinisa ngesandla kuze kuthokomale.

5. Sebenzisa isikrufu ukuze uqinise ukufaka ezincazelweni ezisohlwini lweshadi losayizi wophawu lobuso bendandatho ye-SAE O-ring.

Ukufakwa kwe-ORB Fittings

1. Qala ngokuhlanza ingxenye enentambo yakho kokubili owesilisa nowesifazane.

2. Hlola i-O-ring ukuze uqinisekise ukuthi ayinazo izinkinga.

3. Faka i-O-ring endaweni ene -grooved phansi kwentambo yesilisa.

4. Faka intambo embotsheni yesifazane ngokucophelela ukuze ugweme ukuwela.

5. Qinisa ngokuvumelana -SAE eziqondile zentambo ye-UNF . nezincomo ze

Ukucatshangelwa Kwesondlo

Kokubili ukufakwa kwe-ORFS ne-ORB kudinga ukuhlolwa okujwayelekile koku:

l Gqoka futhi udabule ama -O-rings erabha yokwenziwa.

l Izimpawu zokuvuza ezindaweni zokuvala.

l Ukugqwala kukhabhoni , i-nickel-plated carbon , noma zensimbi engagqwali . izingxenye

l afanelekile Amazinga etorque ukuze kugcinwe uphawu olungavuzi.

Amanothi Okuqhathanisa

l Ukufakwa kwe-ORFS kunendawo eyisicaba yokuvala ecindezela irabha yokwenziwa i-O-ring , ehlinzeka ngensimbi ne-O-ring double seal . Lokhu kuhle ezinhlelweni zokucindezela okukhulu futhi kunciphisa amaphuzu avuzayo.

l Ukufakwa kwe-ORB kusebenzisa ingxenye enentambo kanye ne -chamfer eyenziwe ngomshini phansi ukuze ibambe indandatho ye-O ehlanganisiwe . Avame ukusetshenziswa ezinhlelweni zamapayipi anamandla awuketshezi futhi angakwazi ukumelana nomfutho omkhulu .

l Ukuze kulungiswe , ukufakwa kwe-ORFS ngokuvamile kubhekwa njengokulula ukuhlola ngoba i- O-ring iyabonakala futhi iyafinyeleleka. Ukufakwa kwe-ORB kungase kudinge ukuqaqa ukuze kuhlolwe isimo sendandatho ye -O.

Ukuhlaziya Ngokuqhathanisa: Ukuzivumelanisa nezimo kanye nokuhlukahluka

Uma sikhuluma nge -O-Ring Face Seal (ORFS) kanye ne-O-Ring Boss (ORB) , singena emhlabeni wokufakwa kwe-hydraulic . Lezi izingxenye ezibalulekile ezisiza imishini ukuthi isebenze kahle ngokulawula uketshezi ngaphansi kwengcindezi ephezulu. Manje, ake siqhathanise ukuthi lezi zinhlobo ezimbili zezimvu zivumelana nezimo futhi ziguquguquka kanjani.

Ukuvumelana nezimo Ezimweni Ezihlukene Namazinga Okushisa

l O-Ring Face Seal (ORFS): Lokhu kufakwa kwaziwa ngokuba nzima. Bangakwazi ukusingatha amazinga okushisa aphezulu kanye nezindawo ezihlukahlukene. Cabanga nge- hydraulic excavator esebenza ngosuku olushisayo noma ebusuku obubandayo; Ukufakwa kwe-ORFS kugcina uketshezi lunyakaza ngaphandle kokuvuza. Zinendawo eyisicaba yokuvala eyenza uphawu oluqinile, olulungele izimo zokucindezela okukhulu .

l O-Ring Boss (ORB): Ukufakwa kwe-ORB nakho kunikeza ukuguquguquka okuhle. Banengxenye enemicu kanye nendawo enemisele lapho kuhlala khona i-O-ring. Lo mklamo usiza ukudala uphawu olungamelana namazinga okushisa ahlukene nezingcindezi. Kufana nendlela isivalo esivala ngayo imbiza, kungakhathaliseki ukuthi kushisa noma kubanda ngaphandle.

Ibanga Losayizi Nezinto Zokusebenza Ezitholakalayo ze-ORFS ne-ORB

Kokubili i-ORFS ne-ORB ziza ngobukhulu obuhlukahlukene kanye nezinto zokwakha. Lokhu kusho ukuthi zingasetshenziswa emishinini eminingi eyahlukene, kusukela kuma-forklift kuya kogandaganda.

l Izinto: Uzothola ukufakwa kwe-ORFS ne-ORB okwenziwe ngekhabhoni ye , -nickel-plated carbon , nensimbi engagqwali . Ama-O-rings ngokwawo angase enziwe kusukela ku-Buna-n noma ku-Viton , okuyizinhlobo zama -O-rings erabha yokwenziwa . Lezi zinto zikhethwa ngamandla azo kanye nekhono lokusingatha ingcindezi.

l Osayizi: Kuneshadi likasayizi wophawu lobuso bendandatho ye-SAE O-ring elibonisa wonke ama-O-rings osayizi abahlukene ongawatholela okufakwayo kwe-ORFS. Ukufakwa kwe-ORB kulandela uchungechunge lwe-SAE oluqondile lwe-UNF , okusho ukuthi lwenziwe lwalingana kahle nembobo yentambo yesifazane emishinini eminingi.

Ngamafuphi, i-ORFS ne-ORB zombili zenzelwe ukuthi zivumelane nezimo kakhulu. Angasebenza ezimweni eziningi ezihlukene, kungakhathaliseki ukuthi ukuhlanganiswa kwepayipi le-hydraulic hose noma isistimu yamapayipi asebenza ngogesi . Okubalulekile ukuthi, basiza ukugcina imishini isebenza ngaphandle kokuvuza kwamanzi , okuyinto enkulu uma ufuna umshini wakho uhlale isikhathi eside futhi usebenze kahle.

Ukuhlaziya Ngokuqhathanisa: Ukuvimbela Ukuvuza Nokuphepha

Uma sikhuluma ngokuvimbela ukuvuza kumasistimu asebenza ngogesi, sibheka ukuthi i -O-ring face seal (ORFS) kanye ne -O-ring boss (ORB) bavimba kanjani uketshezi ukuthi lungaphumi. Zombili zisetshenziselwa ukufakwa kwe-hydraulic ukugcina izinto ziqinile futhi zilungile, kodwa zikwenza ngezindlela ezahlukene.

Amandla Okuvimbela Ukuvuza kwe-ORFS ne-ORB

I-ORFS yaziwa ngendandatho yayo ye-O emboziwe ehlala ithokomele endaweni eyisicaba yokuvala ukuxhumana kwabesifazane . Uma ukulingana kowesilisa kuqiniswa, le-O-ring iyashwibeka kahle, kwakheka uphawu olungavuzi . Kufana nokuthi uma ubeka isivalo embizeni eqine kakhulu - akukho ukuchitheka!

Ehlangothini lokuphenya, i-ORB ine- O-ring yokwenziwa yerabha elingana endaweni eyisihosha phansi kwentambo yesilisa . Uma ukulufela intambo yowesilisa embotsheni yentambo yesifazane , i-O-ring iphushelwa emseleni, yenze isivalo esiqinile. Kucabange njengalapho uphusha ipulaki esokhethi; ilingana kahle futhi ayinyakazi.

Ukukhathazeka Kwezokuphepha kanye nokuthi Ukufakwa ngakunye Kubhekana Kanjani Nazo

Ukuphepha kuyinto enkulu, ikakhulukazi uma sibhekene nengcindezi ephezulu ezintweni ezifana namashubhu asebenza ngogesi namapayipi ahlanganisa ipayipi . Kokubili i-ORFS ne -ORB kufanele ibhekane nale ngcindezi ngaphandle kokuyeka.

I-ORFS ingompetha ekufakweni kwengcindezi ephezulu ngoba insimbi yabo ne-O-ring double seal iyabambelela. Bafana namaqhawe anamandla ezimvu zamanzi, agcina wonke umuntu ephephile ekuvuzeni okungase kubangele ukushelela noma imililo ezindaweni ezifana nokwakhiwa ngaphandle komgwaqo noma izimayini..

I-ORB , nakuba inamandla, inendlela ehlukile. Ingxenye eluchungechunge ne -O-ring combo isho ukuthi ilungele ukucindezela okuphezulu , futhi, kodwa kubaluleke kakhulu ukuthola usayizi futhi ilingane kahle. Uma kungenjalo, ungase ube nokuvuza, futhi akekho ofuna lokho. Kufana nokuqinisekisa ukuthi umakalabha webhayisikili wakho ulingana ngaphambi kokuhlehlisa intaba.

Kokubili i ORFS ne -ORB zithatha ukuvimbela ukuvuza nokuphepha - ngezindlela zazo. I-ORFS ingase ibe nomphetho ezimeni zokucindezela okukhulu ngenxa yokubekwa kwayo kabili , kodwa i-ORB iseyinketho eqinile uma ufanisa yonke into ngendlela efanele.

Izindleko Ukucatshangelwa

Uma sikhuluma nge -O-Ring Face Seal (ORFS) kanye ne-O-Ring Boss (ORB) , sibheka izinhlobo ezimbili ezidumile zokufakwa kwe-hydraulic . Zombili zinezici ezihlukene ezithinta izindleko. Ake singene ezindlekweni zokuqala kanye nemithelela yezindleko zesikhathi eside.

Izindleko Zokuqala ze-ORFS vs. Ukufakwa kwe-ORB

Ukufakwa kwe-ORFS kuvame ukubiza kakhulu ngaphambili. Zinendawo eyisicaba yokuvala kanye ne- chamfer efakwe umshini wokubamba i -O-ring . Lo mklamo udinga ukunemba okwengeziwe ekukhiqizeni. Okufakwayo kwe-ORB, nengxenye yakho enentambo kanye ne-O-ring ehlanganisiwe , kulula futhi kuvame ukubiza kancane ekuqaleni.

Izindleko Zesikhathi Eside

Ngokuhamba kwesikhathi, izindleko zingashintsha. Ukufakwa kwe-ORFS, ngensimbi yakho kanye ne-O-ring double seal , kungase kuhlale isikhathi eside. Lokhu kusho ukuthi imali encane esetshenziswe ekushintsheni. Okufakwayo kwe-ORB, kuyilapho kushibhile ekuqaleni, kungase kudinge ukunakekelwa okwengeziwe. Zinendawo enomsele phansi kwentambo yesilisa . Uma lokhu konakaliswa, ukuvuza kungenzeka.

Kokubili i-O-ring face seal fitting kanye ne-O-ring boss seal banezindlela zabo zokuvala . I-ORFS isebenzisa indawo eyisicaba yokuvala , kuyilapho i-ORB isebenzisa umsele . Lo mehluko ungathinta ukuthi udinga kaningi kangakanani ukushintsha izingxenye.

Kuzinhlelo zokusebenza ezinomfutho ophezulu , njengasohlelweni lwemboni noma ukwakhiwa ngaphandle komgwaqo , i-ORFS ingaba ngcono. Zenzelwe ukuphatha izingcindezi zokusebenza ngaphandle kokudala izindawo ezivuzayo . Ngakho-ke, bangakongela imali yesondlo ngokuhamba kwesikhathi.

Ukufakwa kwe-ORB, ngakolunye uhlangothi, kuhle uma udinga uphawu oluthembekile kodwa mhlawumbe ungenaso isabelomali se-ORFS. Asetshenziswa ezindaweni eziningi futhi, njengama- hydraulic excavators , loaders , forklifts , kanye nogandaganda..

Ukukhetha Okulungile

Uma kukhulunywa ngokufakwa kwe-hydraulic, kubalulekile ukukhetha okulungile. Ungase ukhethe phakathi kwe- O-ring face seal (ORFS) kanye ne- O-ring boss (ORB) . Zombili zinezinzuzo zazo. Nakhu ongacabanga ngakho:

Izinto Okufanele Zicabangele

1. Izingcindezi Zokusebenza : Ukufakwa kwe-ORFS kuhle ngomfutho ophezulu. Angakwazi ukuphatha amandla amaningi ngaphandle kokuvuza.

2. Amaphuzu Avuzayo : I-ORB inamaphuzu ambalwa avuzayo. Lokhu kungenxa yokuthi i-O-ring ivaleleke emseleni.

3. Idizayini Yesistimu : Cabanga ngesimo sohlelo lwakho. I-ORFS inendawo eyisicaba yokuvala, edinga indawo eyengeziwe.

4. Materials : Kokubili i-ORFS ne-ORB ziza ngezinto ezifana nekhabhoni, insimbi engagqwali , kanye nama-O-rings enziwe nge -Buna-n noma i-Viton.

5. Indlela Yokuvala : I-ORFS yenza uphawu ngokucindezela i-O-ring. I-ORB isebenzisa ingxenye enentambo kanye nendawo eyenziwe ngomshini we-chamfer ukuze ivalwe.

Izimo ze-ORFS ne-ORB

l ORFS : Ilungele amashubhu ane-flanged kanye nezinhlelo zokusebenza ezibolayo . Zinensimbi kanye ne-O-ring double seal, enokwethenjelwa kakhulu.

l ORB : Ilungele uma isikhala siqinile. Banokuxhumana kowesilisa nowesifazane . okuhambisana kahle

I-Case Study : Ku-excavator ye-hydraulic, ukufakwa kwe-ORFS kwasetshenziswa ngoba kwakukwazi ukusingatha izicelo zokucindezela okuphezulu futhi kulula ukuzinakekela.

Iqiniso : Ngokwamazinga afana ne -SAE J1453 ne-ISO 8434-3 , i-ORFS yakhelwe ukuqeda ukuvuza ekuhlanganiseni kwepayipi le-hydraulic hose..

I-Quote : 'Ngokuhlangenwe nakho kwethu, ukufakwa kwe-ORFS kwehlise kakhulu ukuvuza koketshezi ezikhumulweni ze-NPT ,' kusho uchwepheshe weqembu labadayisi ophuma enkampanini ehamba phambili yama-adaptha osebenzisa amanzi .

Lapho ukhetha, khumbula ukuthi i-ORFS ingaba ngcono kungcindezi ephezulu nalapho udinga isistimu engavuzi . I-ORB ingaba yinketho yezikhala eziqinile kanye namaphoyinti avuzayo ambalwa.

Ukufakwa okulungile kugcina izinhlelo zakho zehydraulic zisebenza kahle. Imayelana nezingxenye zekhwalithi nokusebenza kahle kwesistimu . Ngakho-ke, lapho uthatha isinqumo, cabanga ngokufakwa kwezigxivizo zeshadi , likasayizi wophawu lobuso bendandatho ye-SAE O-ring , kanye nosayizi ohlukile we-O-ring ongase uwadinge.

Okwenziwa yizimboni njenge- forklift, ugandaganda , noma amavalvu , ufuna ukwenza isiqiniseko sokuthi unophawu olulungile. Noma ngabe i-ORFS noma i-ORB , ngayinye inendawo yayo. Qiniseka ukuthi uhlola izidingo zesistimu yakho bese ukhetha ukulingana okufana nalezo zidingo kangcono kakhulu.

Imibuzo Evame Ukubuzwa Nge-ORFS kanye Nokufakwa Kwe-ORB

Yini ehlukanisa ukufakwa kwe-ORFS ne-ORB mayelana nengcindezi yokuvala?

Ukufakwa kwe -O-ring face seal (ORFS) kwaziwa ngamakhono azo wokucindezela okuphezulu . Anendawo eyisicaba yokuvala ecindezela i -O-ring , ehlinzeka ngokuvala okuqinile . Ngokuphambene, okokufaka kwe -O-ring boss (ORB) kusebenzisa ingxenye enentambo kanye nezindandatho zerabha zokwenziwa ukuze kuvalwe uphawu, okusebenza kahle kodwa okungenzeka kungafani nokucindezela kokuvala kwe-ORFS kwezinye izimo.

Ingabe ukufakwa kwe-ORB kungasetshenziswa esikhundleni se-ORFS ezindaweni ezidlidliza kakhulu?

Ukufakwa kwe-ORB, ngochungechunge lwakho lwe-SAE oluqondile lwe-UNF , kuqinile. Nokho, ezindaweni zokudlidliza okuphezulu , ukufakwa kwe-ORFS kungase kube ngcono ngoba insimbi yayo ne-O-ring double seal kunciphisa ubungozi bokuvuza.

Ngabe ukusebenza kahle kwezindleko kwe-ORFS kuqhathaniswa kanjani ne-ORB esikhathini eside?

Ngokuhamba kwesikhathi, i-ORFS ingase ingabizi kakhulu ngenxa yempilo ende yesevisi nokusebenza kwayo okungavuzi . Ukufakwa kwe-ORB kungase kudinge ukunakekelwa okwengeziwe , ikakhulukazi ezinhlelweni zokucindezela okukhulu.

Ingabe zikhona izimboni ezithile ezikhetha i-ORFS kune-ORB, futhi ngani?

Yebo, izimboni ezifana nokwakhiwa kwangaphandle kwemigwaqo kanye nezimayini zithanda i-ORFS ngenxa yokuqina kwayo ezicelweni ezinengcindezi ephezulu kanye nezonakalisayo . Bangakwazi ukubhekana nezingcindezi zokusebenza ezinamaphoyinti ambalwa okuvuza.

Yiziphi izinto ezicatshangelwayo zokuphepha eziyinhloko lapho ukhetha phakathi kokufakwa kwe-ORFS ne-ORB?

Ukuphepha kusemqoka. Ukufakwa kwe-ORFS kunikeza uphawu oluthembekile , okunciphisa ubungozi bokuvuza koketshezi . Ukufakwa kwe-ORB kufanele kufakwe ngendlela efanele ukuze kuqinisekiswe ukuphepha, ikakhulukazi kumasistimu anengcindezi ephezulu.

Ukushintshashintsha kwezinga lokushisa kukuthinta kanjani ukukhetha phakathi kwe-ORFS ne-ORB?

Ukushintsha kwezinga lokushisa kungathinta ukufakwa. Okufakwayo kwe-ORFS kunomklamo oqinile obhekana kahle nokuhlukahluka kwezinga lokushisa, okugcina uphawu oluqinile . I-ORB ingase idinge ukunakwa okwengeziwe ukuze uqinisekise ukuthi i- O-ring ayihluleki ngaphansi kwamazinga okushisa adlulele.

Yiziphi izinselele zokulungisa ezijwayelekile ezihlobene nokufakwa kwe-ORB?

Ukulungiswa kokufakwa kwe-ORB kungase kuhlanganise ukuhlola ama-O-rings ukuthi agugile futhi aklebhukile kanye nokuqinisekisa ukuthi imicu ayonakaliswa. Ukuhlola okuvamile kusiza ukuvimbela ukuvuza koketshezi.

Kukuziphi izimo lapho ukufakwa kwe-ORFS kungathathwa njengokungafaneleki kune-ORB?

Ukufakwa kwe-ORFS kungase kungafaneleki uma kunesikhala esilinganiselwe ngenxa yokuthi kukhulu. Okufakwayo kwe-ORB kunephrofayela encane, okuyenza ilingane kahle nezikhala eziqinile.

Zihluke kanjani izinketho zempahla ye-ORFS ne-ORB yokufakwayo?

Izinto ezifana nekhabhoni, i-nickel-plated carbon , nensimbi engagqwali zivamile kukho kokubili. Kodwa, okokufaka kwe-ORFS kuvame ukusebenzisa i-Buna-n noma i-Viton kuma-O-rings, kuyilapho i-ORB inosayizi ohlukile wezinketho ze-O-ring ukuze ilingane nendawo enomsele..

Yimaphi amathiphu okufaka angasiza ekuqinisekiseni uphawu olufanele nge-ORFS nokufakwa kwe-ORB?

Ukuze uthole uphawu oluhle, qiniseka ukuthi izindawo ezingaphezulu zihlanzekile. Ku-ORFS, qondanisa indawo yokuvala eyisicaba ngendlela efanele. Ku-ORB, qinisekisa ukuthi i- O-ring ihlala khona kanye endaweni eyi-grooved futhi ayimpintshwa ngesikhathi sokufakwa.

Ingabe I-ORFS kanye Nokufakwa Kwe-ORB Kungashintshaniswa?

Ngokuvamile, cha. I-ORFS ne-ORB zinezindlela ezihlukene zokulutha nezindlela zokuvala . Ukusebenzisa uhlobo olungalungile kungaholela ekuvuzeni nasezinkingeni zokuphepha . Njalo hlola nethimba lakho labadayisi noma imininingwane yokuxhumana enikezwe umkhiqizi ukuze uthole isiqondiso.

Isiphetho: Ukuqinisekisa Ukusebenza Okufanelekile KumaHydraulic Systems

Kulesi sihloko, sihlole umehluko phakathi kokufakwa kwe-O-ring face seal (ORFS) kanye nokufakwa kwe-O-ring boss (ORB) . Nasi isifinyezo esisheshayo salokho esikufundile:

l Ukufakwa kwe -ORFS kunendawo eyisicaba yokuvala kanye ne -chamfer eyenziwe ngomshini ebamba i -O-ring endaweni.

l kwe-ORB kunengxenye Okufakwayo enentambo futhi kusebenzisa indandatho ye-O ebekwe endaweni egobile phansi kwentambo yesilisa ukuze kwakhe uphawu.

Isifinyezo Sokuthatha Okubalulekile

l Ukufakwa kwe-O-ring face seal kuhle kakhulu ezinhlelweni zokucindezela okukhulu futhi kusiza ukuvimbela ukuvuza.

l I -O-ring boss seal fitting iguquguquka futhi isetshenziswa ezinhlelweni ezahlukahlukene zezimboni.

l Amazinga e -SAE J1453 kanye ne-ISO 8434-3 aqondisa ukusetshenziswa kwalokhu kufakwa.

Imikhuba Engcono Kakhulu Yokukhetha Nokugcina Ukufakwa Kwendandatho ye-O

Lapho ukhetha ukufakwa okulungile kwamasistimu akho asebenza ngaphansi komhlaba , cabangela lezi zindlela ezihamba phambili:

1. Yazi Isicelo Sakho : Amasistimu ahlukene adinga ukufakwa okuhlukile. Isibonelo, i-ORFS ivame ukusetshenziswa ekwakhiweni kwemigwaqo kanye nasezimayini ngoba iphatha kahle umfutho ophakeme .

2. Hlola okokusebenza : Ukufakwa kuza ngekhabhoni, i-nickel-plated carbon , nensimbi engagqwali . Ama-O-rings enziwe ngezinto ezifana ne -Buna-n ne -Viton . Khetha leyo ehambisana nezidingo zesistimu yakho.

3. Sebenzisa usayizi olungile : Qiniseka ukuthi usebenzisa ishadi likasayizi wophawu lobuso bendandatho ye-SAE O-ring ukuze uthole usayizi olungile we-O-ring ukuze ulingane kahle.

4. Ukunakekela Okuvamile : Hlola ukufakwa kwendandatho yakho ye-O ukuthi ayigugile yini. Zishintshe uma zikhombisa izimpawu zokulimala ukuze zingavuzi.

5. Xhumana Nochwepheshe : Uma ungenaso isiqiniseko, khuluma nethimba lakho labadayisi noma uthinte ama-adaptha asebenzisa amanzi kanye nabahlinzeki bamashubhu ukuze uthole iseluleko.

Khumbula, noma ngabe usebenza ku- hydraulic excavator , loaders , forklift , noma ugandaganda , efanele indlela yokuvala ingasho umehluko phakathi kwesistimu engavuzi kanye naleyo enezinkinga.

Ekunakekeleni okokufaka kwakho:

l Njalo hlola izindawo ezivalekayo ukuze uthole umonakalo.

l Qinisekisa ukuthi ama-O-rings erabha yokwenziwa awasikekile futhi awakhubazekile.

l Qinisa ukufakwa ezincazelweni ezinconyiwe ukuze ugweme ukucindezela ngokweqile iringi ye-O.

Ngokulandela lezi zinqubo, ungasiza ekuqinisekiseni ukusebenza okuphelele nempilo ende yesevisi yamasistimu akho e-hydraulic . Njalo beka phambili izingxenye zekhwalithi ukuze ugcine ukusebenza kahle kwesistimu . Khumbula, inhloso ukugcina isistimu yakho isebenza ngaphandle kokuvuza koketshezi noma amaphuzu avuzayo.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu