Yu dɔn ɛva wɔnda bɔt di difrɛn kayn haydrolik O-ring fitin dɛn ɛn di tin dɛn we dɛn kin yuz fɔ mek dɛn? A no aw i kin kɔnfyus wit bɔku opshɔn dɛn we de de. Na dat mek a de ya - fɔ gayd una tru di intrikɛt wɔl fɔ haydrolik fitin dɛn, mɔ fɔ pe atɛnshɔn pan di O-ring fes sil (ORFS) ɛn O-ring bɔs (ORB) fitin dɛn. Pan ɔl we dɛn tu fitin ya rili impɔtant fɔ mek dɛn mek wan sikrit sil na haydrolik sistem, dɛn ɔl tu gɛt dɛn yon wok ɛn bɛnifit dɛn. Tide, wi go unravel di mystery bihain dis tu popular taips. Dɛn kin tan lɛk tɛknikal wɔd dɛn fɔs, bɔt a de ashu yu, fɔ ɔndastand dɛn na di men tin fɔ mek yu gɛt haydrolik kɔnɛkshɔn dɛn we nɔ gɛt lik. So, kam wit mi as wi de eksplore di nyuans dɛm fɔ ORFS ɛn ORB fitin dɛm ɛn fɛn ɔut wetin mek dɛn kin bi di pafɛkt fit fɔ yu haydrolik sistɛm nid dɛm. Lɛ wi dayv insay dis togɛda ɛn mek sɛns to di wɔl fɔ haydrolik fitin!

Ɔndastand di O-Ring Fes Sil (ORFS) Fitin dɛn

Difinishɔn ɛn Dizayn fɔ ORFS Fitin dɛn

![1F ORFS MALE O-RING orfs haydrolik fitin]()

1F ORFS MALE O-RING orfs haydrolik fitin

O-Ring Face Seal (ORFS) fitin na wan kayn haydrolik fitin . Dɛn gɛt flat say fɔ sidɔm ɛn wan sintetik rɔba O-ring we dɛn put insay wan grov. We yu kɔnɛkt wan ORFS fitin, di O-ring de kɔmprɛs , we de mek wan sil we rili tayt. Dis na di rizin we mek dɛn kɔl ORFS as wan we fɔ sial we nɔ de lik .

Standart ɛn Spɛsifikeshɔn dɛn: SAE J1453 ɛn ISO 8434-3

ORFS fitin dɛn fɔ mit sɔm patikyula standad dɛn. Di SAE J1453 ɛn ISO 8434-3 na lɔ dɛn we dɛn fitin dɛn ya de fala. Dɛn standad ya de ɛp fɔ mek shɔ se ORFS fitin dɛn de wok fayn na haydrolik sistem dɛn . Dɛn kin tɔk bɔt aw dɛn fɔ mek di fitin dɛn, us saiz dɛn fɔ bi, ɛn aw dɛn fɔ tɛst dɛn.

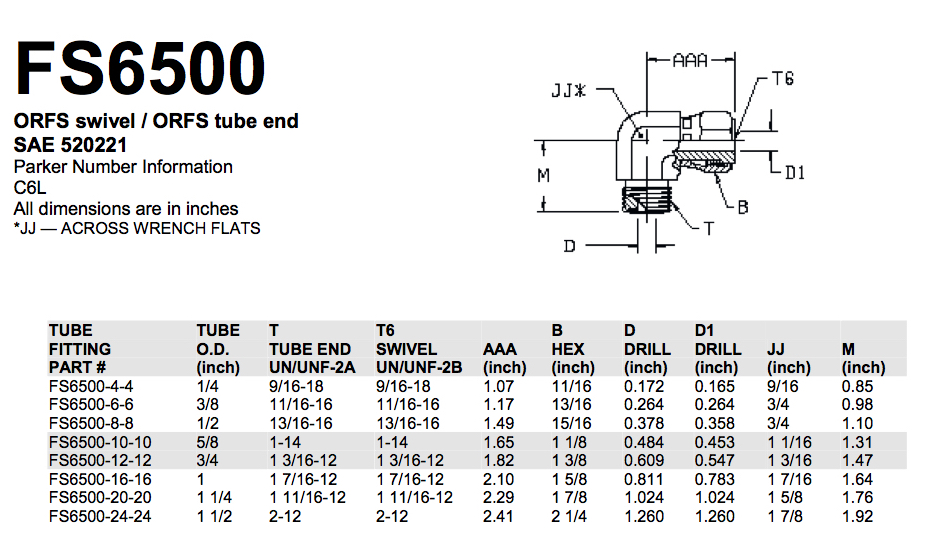

![FS6500 ORFS swivel / ORFS tube end SAE 520221 elbow connector FS6500 ORFS swivel / ORFS tiub ɛnd SAE 520221 ɛlb kɔnɛkta]()

FS6500 ORFS swivel / ORFS tiub ɛnd SAE 520221 ɛlb kɔnɛkta

Aplikeshɔn ɛn Advantej dɛn fɔ ORFS Fitin dɛn na Haydrolik Sistɛm dɛn

ORFS fitin dɛn fayn fɔ haydrolik sistem bikɔs dɛn nɔ de lik. Dɛn kin yuz dɛn fɔ du tin dɛn we gɛt ay prɛshɔn lɛk haydrolik ɛkskavata, loda, fɔklift, ɛn trakta . Wan big plus na dat dem kin handle opareshon preshos witout kriet lik point.

![ORFS tube ends SAE 520432 couplings and tee ORFS tyub end SAE 520432 kopl ɛn tee]()

ORFS tyub end SAE 520432 kopl ɛn tee

Sayz ɛn Kɔmpatibiliti Kɔnsidɛreshɔn fɔ ORFS Fitin dɛn

We yu pik wan ORFS fitin, saiz na di ki. Yu fɔ mek shɔ se i fit di haydrolik tubing ɔ hos asɛmbli we yu de wok wit. Di SAE O-ring fes sil saiz chart de ɛp yu fɔ fɛn di rayt difrɛn saiz O-ring fɔ yu wok. I impɔtant fɔ mek yu mach di man fitin ɛn di uman kɔnekshɔn kɔrɛkt wan. Dis kin mek shɔ se di say dɛn we dɛn kin sidɔm de tɔch di rayt we ɛn di O-ring kin sial fayn fayn wan.

ORFS fitin dɛn kin kam insay difrɛn matirial dɛn. Yu kin fɛn dɛn insay kabɔn, kabɔn we dɛn plet nikel , ɛn stenlɛs stiɛl . Dɛn mek di O-ring dɛn wit tin dɛn lɛk Buna-n ɛn Viton . Dis min se yu kin yuz dɛn na bɔku industrial aplikeshɔn dɛn.

O-Ring Face Seal fittings na smat choice fɔ haydrolik sistem . Dɛn de fala di SAE J1453 ɛn ISO 8434-3 standad dɛn. Dɛn kin wok fayn bikɔs dɛn nɔ kin lik ɛn dɛn kin ebul fɔ bia wit ay prɛshɔn . Mek shɔ se yu chɛk di saiz dɛn fayn fayn wan yuz di SAE O-ring fes sil saiz chɔt . Dis go ɛp yu fɔ fɛn di rayt fit fɔ yu haydrolik adapt ɛn tubing . If yu gɛt kwɛstyɔn, go to wan tim we de sɛl . Dɛn kin gi yu di kɔntakt ditil ɛn mɔ infɔmeshɔn.

Eksplɔrɔ O-Ring Bos (ORB) Sil Fitin dɛn

Diskripshɔn ɛn Strukchɔ fɔ ORB Fitin dɛn

![SAE O-ring boss SAE 140257 man threaded konektor]()

SAE O-ring boss SAE 140257 man threaded konektor

O-ring bos fitin, ɔ ORB fɔ shɔt, na wan kayn haydrolik fitin . Dɛn gɛt wan man fitin wit wan stret trɛd ɛn wan chamfer we dɛn mek wit mashin fɔ ol wan O-ring . Di uman kɔnɛkshɔn gɛt pat we gɛt trɛd ɛn flat say fɔ sidɔm . We yu tayt di tu pat dɛn, di O-ring kin kɔmprɛs , ɛn dis kin mek i tayt.

Standart ɛn Spɛsifikeshɔn dɛn: ISO 11926-1 ɛn SAE J1926-1

ORB fitin dɛn de fala sɔm patikyula standad dɛn. ISO 11926-1 ɛn SAE J1926-1 na di men wan dɛn. Dɛn wan ya de sɛt di lɔ dɛn fɔ di SAE stret UNF trɛd we dɛn yuz na dɛn fitin ya. Dɛn de mek shɔ se ɔl di ORB fitin dɛn fit togɛda fayn fayn wan insay wan fluid pawa paip sistem.

Kɔmɔn Yuz ɛn Bɛnifit dɛn fɔ ORB Fitin dɛn na Indastri

ORB fitin dɛn de ɔlsay na di industri. Dɛn kin yuz dɛn fɔ mek haydrolik ɛkskavata, lod, fɔklift, ɛn trakta . Dɔn bak, yu kin fɛn dɛn na valv ɛn petrol gas sistem . Di bɛnifit dɛn we pɔsin kin gɛt? Dɛn fayn fɔ ay-prɛshɔn aplikeshɔn ɛn dɛn kin ɛp fɔ mek i nɔ lik. Dɛn kin las fɔ lɔng tɛm ɛn kip di sistɛm efyushɔn ay.

Sayz ɛn Sɛlɛkshɔn Krayteria fɔ ORB Fitin dɛn

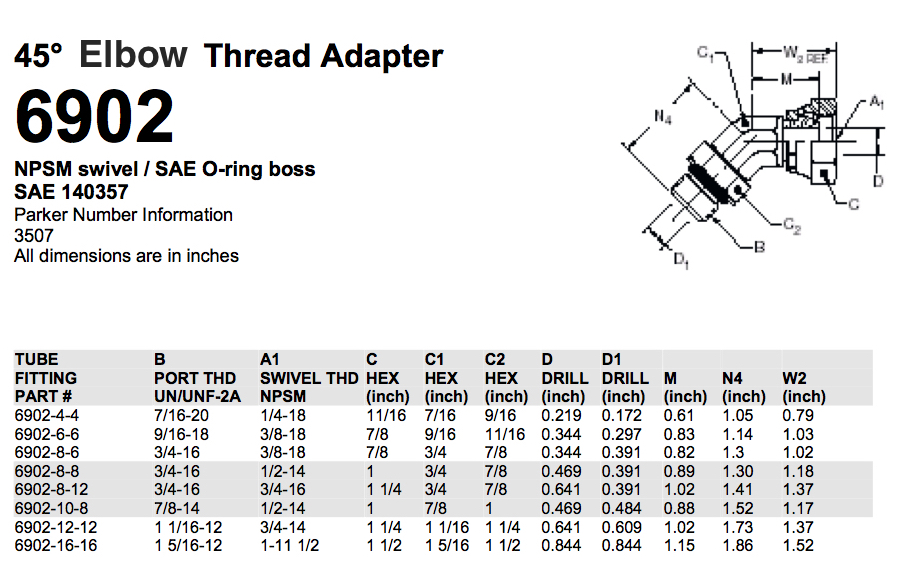

![SAE O-ring boss SAE 140357 45° Elbow Thread Adapter metal pipe connector SAE O-ring boss SAE 140357 45° Elbow Thread Adapter metal paip konektor]()

SAE O-ring boss SAE 140357 45° Elbow Thread Adapter metal paip konektor

We yu de pik di rayt ORB fitin, yu fɔ tink bɔt saiz. Di SAE O-ring fes sil saiz chart de ɛp yu fɔ fɛn di difrɛn saiz O-ring we yu nid. Dɔn bak, luk wetin dɛn mek di fitin wit. Di tin dɛn we yu kin pik na kabɔn, kabɔn we dɛn plet nikɛl, stenlɛs stiɛl, Buna-n, ɛn Viton . Mek shɔ se di durometer (hardness) fɔ di O-ring mach yu nid.

We yu pik wan ORB fitin, yu de luk fɔ wan nɔ-lik sil na yu haydrolik sistem . Mɛmba se di say dɛn we dɛn kin sidɔm fɔ klin ɛn di O-ring fɔ gɛt di rayt saiz. If yu nid ɛp, tɔk to wan sɛl tim we no bɔt haydrolik adapt ɛn tubing.

In shot, ORB fitin na wan we fɔ sial we de yuz sintetik rɔba O-ring . Dɛn gud fɔ ay prɛshɔn ɛn dɛn nɔ de lik bɔku. Di SAE J1926-1 ɛn ISO 11926-1 standad dɛn de mek shɔ se dɛn wok fayn na industrial aplikeshɔn dɛn . We yu nid fɔ pik wan, chɛk di sayz chɔt ɛn wetin dɛn mek di fitin wit.

Komparativ Analysis: O-Ring Fes Sil Vs. O-Ring Boss na yu

Ki Similarities bitwin ORFS ɛn ORB Fitin dɛn

We wi luk O-Ring Face Seal (ORFS) ɛn O-Ring Boss (ORB) fitin, i tan lɛk se yu kɔmpia tu tɔp atlet dɛn. Dɛn difrɛn, bɔt dɛn gɛt bɔku tin dɛn bak we kɔmɔn. Lɛ wi brok dɔŋ di tin dɛn we dɛn fiba.

ORFS ɛn ORB ɔl tu de yuz sintetik rɔba O-ring fɔ mek i nɔ lik. Dɛn O-ring ya rili impɔtant fɔ mek shɔ se di wata we de kɔmɔt fayn fayn wan insay di paip dɛn, fɔ mek dɛn nɔ rɔsh ɔ lik.

Insay ɔl kayn ikwipmɛnt, frɔm haydrolik ɛkskavatɔ to fɔklift, yu go si se dɛn fitin ya de ple impɔtant pat. Dɛn impɔtant na haydrolik sistɛm, dɛn de manej ay prɛshɔn wit sɛns fɔ mek shɔ se ɔltin de wok fayn fayn wan ɛn kip di wata we de insay.

Trɛd tan lɛk sikrit kɔd we de ɛp fitin dɛn fɔ kɔnɛkt ɛn tɔk to dɛnsɛf. ORFS ɛn ORB ɔl tu de yuz dis kɔd, wit di SAE stret UNF trɛd we na dɛn shered langwej. Dis na aw di man ɛn uman pat pan di fitin dɛn kin kɔnɛkt ɛn de togɛda.

Kɔmparativ Analysis ɔf Siling Mɛkanism dɛn

We wi de tɔk bɔt haydrolik fitin , bɔku tɛm wi kin tink bɔt aw dɛn kin mek wata nɔ lik kɔmɔt. Tu kɔmɔn kayn dɛn na di O-ring fes sil (ORFS) ɛn di O-ring bɔs (ORB) . Lɛ wi dayv insay aw dɛn de wok ɛn aw dɛn de stak agens dɛnsɛf.

Di Mɛkanism fɔ Sial

ORFS ɛn ORB ɔl tu gɛt dɛn yon we fɔ sial. Dɛn kin yuz wan pat we dɛn kɔl O-ring . Dis na wan lɔp we dɛn mek wit sintetik rɔba we kin squish fɔ stɔp di wata fɔ kɔmɔt.

Aw ORFS De Achieve wan Sil

Di O-ring fes sil fitin gɛt flat say. We yu tayt am, di O-ring kin prɛs bitwin dis flat silin say ɛn di uman kɔnɛkshɔn . I tan lɛk se yu de pres yu an pan spɔnj fɔ sok wata. Na mɛtal ɛn O-ring dabl sil , we min se i rili gud fɔ kip tin dɛn tayt.

Aw ORB De Achiev wan Sil

O-ring bos fitin de wok smɔl difrɛn we. Dɛn gɛt pat we gɛt trɛd ɛn wan say we gɛt grov na di man trɛd in biɛn . We di man fitin skru insay di uman trɛd pɔt , di O-ring we de na di grov kin squish. Dis kin mek wan tayt sil rawnd di pat we gɛt trɛd.

Kɔmpia di Silin Efyushɔn

ORFS ɛn ORB ɔl tu fayn fɔ stɔp lik na ay-prɛshɔn aplikeshɔn lɛk insay haydrolik ɛkskavatɔ ɔ fɔklift . Bɔt, sɔm difrɛns dɛn de.

l ORFS na jεnarali dεn kin kכnsidr am bεtε fכ hεy-prεshכ n situeshכn. I gɛt flat siling surface we kin ebul fɔ handle mɔ fos we nɔ lik.

l ORB na smɔl mɔ versatile. I kin fit insay difrɛn saiz pɔt dɛn, we kin izi fɔ yuz insay industrial aplikeshɔn dɛn.

In a fluid power piping system , yu want fɔ mek shɔ se yu de yuz di rayt pat dɛn. ORFS kin bɛtɛ fɔ sɔntin we de ɔltɛm ɔnda bɔku prɛshɔn, lɛk haydrolik tubing . ORB kin bi di we fɔ go fɔ pat dɛn we nid fɔ fit na bɔku difrɛn ples dɛn, lɛk haydrolik adapt.

We yu de pik bitwin ORFS ɛn ORB , tink bɔt wetin yu nid. If yu nɔ shɔ, yu kin aks wan sɛl tim we no bɔt haydrolik hos asɛmbli . Dɛn kin ɛp yu fɔ pik di rayt sil fitin fɔ yu wok.

Kɔmparativ Analysis: Prɛshɔn Rɛtin

We wi de tɔk bɔt haydrolik fitin dɛn lɛk di O-ring fes sil (ORFS) ɛn di O-ring bɔs (ORB) , wi de rili tɔk bɔt aw dɛn de handle prɛshɔn. Mek wi brok am daun so e bi super klia.

Prɛshɔn Handlin Kapabiliti dɛn fɔ ORFS

Di O-ring fes sil fitin na sta we i kam pan prɛshɔn. Dɛn mek am wit wan flat silin sɔfa we di sintetik rɔba O-ring dɛn kin sidɔm pan. Dis setup rili gud fɔ handle ay prɛshɔn. infakt, ORFS kin tek prεshכn we go rich 6000 psi. Dat tan lɛk we yu gɛt smɔl ɛlifant we tinap pan ɛni skwea inch!

Prɛshɔn Handlin Kapabiliti dɛn fɔ ORB

Naw, lɛ wi chat bɔt di O-ring bɔs sil fitin . ORB de yuz wan pat we gɛt trɛd ɛn wan eria we dɛn mek wit chamfer mashin usay di O-ring de sidɔm. Na tof pleya tu, bot i kin handle likli les preshos dan ORFS, arawnd 3000 to 5000 psi dipen pan di saiz.

Situeshɔn dɛn We Dɛn Go Plɛs Wan Pas di Ɔda wan Bays pan Prɛshɔn

So, ustɛm wi kin pik wan pas di ɔda wan? Imajin se yu gɛt haydrolik ɛkskavatɔ ɔ fɔklift . Dɛn mashin dɛn ya nid fitin dɛn we go ebul fɔ handle siriɔs prɛshɔn we nɔ go lik. Insay ay-prɛshɔn sityueshɔn lɛk dis, yu go mɔs go wit O-ring fes sil bikɔs dɛn bil am fɔ handle di strɛs.

Bɔt nɔto ɔl wok de bɔt di prɛshɔn we pas ɔl. Sɔntɛnde, yu kin gɛt trakta ɔ loda we nɔ de push di limit dɛn. Insay dɛn kayn tin ya, wan O-ring bɔs sil kin bi di rayt pik. I stil strɔng bɔt i kin fit bɛtɛ wit di sistɛm dizayn ɛn prɛshɔn nid.

Instɔlɛshɔn ɛn Mentɛnans

We i kam pan haydrolik fitin , tu pɔpul kayn dɛn na di O-ring fes sil (ORFS) ɛn O-ring bɔs (ORB) . Dɛn ɔl tu gɛt dɛn yon instɔleshɔn stɛp ɛn mentenɛns kɔnsidareshɔn.

Instɔlɛshɔn fɔ ORFS Fitin dɛn

1. Klin ɔl di komponent dɛn bifo yu instɔl am fɔ mek dɛn nɔ gɛt dɔti.

2. Lubrik di O-ring wit wan kɔmpatib fluid fɔ mek shɔ se i sial fayn.

3. Put di O-ring pan di flat siling surface fɔ di man fitin.

4. Align di man fitin wit di uman kɔnekshɔn ɛn tayt wit yu an te i snug.

5. Yuz wan rench fɔ tayt di fitin to di spesifikeshɔn dɛn we de na di SAE O-ring fes sil saiz chɔt.

Instɔlɛshɔn fɔ ORB Fitin dɛn

1. Start bay we yu klin di pat we gɛt trɛd pan di man ɛn uman fitin dɛn.

2. Inspek di O-ring fɔ mek shɔ se i nɔ gɛt ɛnitin fɔ du wit am.

3. Instɔl di O-ring insay di grov eria na di bays pan di man trɛd.

4. Tred di man fitin insay di uman trɛd pɔt fayn fayn wan fɔ mek i nɔ krɔs-trɛd.

5. Tayt akɔdin to di SAE stret UNF trɛd standad rɛkɛmɔndeshɔn dɛn.

Di Tin dɛn we Yu fɔ Tink bɔt fɔ Mek di Tin dɛn we Yu De Mek

Ɔl tu di ORFS ɛn ORB fitin dɛn nid fɔ de chɛk ɔltɛm fɔ:

l Wear ɛn tear pan di sintetik rɔba O-ring dɛn.

l Sayn dɛm fɔ lik na di say dɛm we dɛn de sidɔm.

l Kɔrɛshɔn pan kabɔn, nikɛl-plet kabɔn , ɔ stenlɛs stiɛl kɔmpɔnɛnt dɛn.

l Prɔpa tɔk lɛvɛl fɔ mek yu kɔntinyu fɔ gɛt nɔ-lik sil.

Notis dɛn fɔ Kɔmpia

l ORFS fitin dɛn gɛt flat silin sɔfays we de kɔmprɛs wan sintetik rɔba O-ring , we de gi wan mɛtal ɛn O-ring dabl sil . Dis na fayn tin fɔ ay-prɛshɔn aplikeshɔn ɛn i de mek di lik poɛnt dɛn nɔ bɔku.

l ORB fitin dɛn de yuz wan pat we gɛt trɛd ɛn wan chamfer we dɛn mek wit mashin na di bays fɔ ol di O-ring we dɛn dɔn kapsul . Bɔku tɛm dɛn kin yuz dɛn na fluid pawa paip sistem ɛn dɛn kin ebul fɔ handle ay prɛshɔn bak.

l Fɔ mentenɛns , ORFS fitin dɛn kin jɔs tek am se i izi fɔ inspɛkt bikɔs di O-ring de si ɛn pɔsin kin ebul fɔ go de. ORB fitin dɛn kin nid fɔ disassembly fɔ chɛk di kɔndishɔn fɔ di O-ring.

Kɔmparativ Analysis: Adaptabiliti ɛn Vɛsatiliti

We wi de tɔk bɔt O-Ring Face Seal (ORFS) ɛn O-Ring Boss (ORB) , wi de dayv insay di wɔl fɔ haydrolik fitin . Dis na impɔtant pat dɛn we de ɛp mashin dɛn fɔ wok fayn fayn wan bay we dɛn de manej wata we de ɔnda ay prɛshɔn. Naw, lɛ wi kɔmpia aw dɛn tu kayn sil dɛn ya kin ebul fɔ adap ɛn dɛn kin ebul fɔ du bɔku tin dɛn.

Fleksibiliti na Difrɛn Envayrɔmɛnt ɛn Tɛmpratura

l O-Ring Face Seal (ORFS): Dɛn no dɛn fitin ya fɔ bi taf. Dɛn kin ebul fɔ bia wit di tɛmpracha we pasmak ɛn difrɛn say dɛn. Tink bɔt wan haydrolik ɛkskavata we de wok pan hot de ɔ kol nɛt; ORFS fitin dɛn de kip di fluid dɛn de muv we nɔ de lik. Dɛn gɛt flat siling surface we de mek tayt sial, we fayn fɔ ay-prɛshɔn situeshɔn.

l O-Ring Boss (ORB): ORB fitin dɛn de gi gud fleksibiliti bak. Dɛn gɛt pat we gɛt trɛd ɛn wan say we gɛt grov usay di O-ring de sidɔm. Dis dizayn de ɛp fɔ mek wan sil we go ebul fɔ bia wit difrɛn tɛmpracha ɛn prɛshɔn. I tan lɛk aw lid kin sial wan jɔg tayt, ilɛksɛf i wam ɔ kol na do.

Rɛnj ɔf Sayz ɛn Matirial dɛn we de fɔ ORFS ɛn ORB

ORFS ɛn ORB ɔl tu gɛt difrɛn saiz ɛn matirial dɛn. Dis min se dɛn kin yuz dɛn na bɔku difrɛn mashin dɛn, frɔm fɔklift to trakta.

l Di tin dɛn we dɛn yuz: Yu go si ORFS ɛn ORB fitin dɛn we dɛn mek wit kabɔn , nikɛl-plet kabɔn , ɛn stenlɛs stiɛl . Di O-ring dɛnsɛf kin bi frɔm Buna-n ɔ Viton , we na kayn sintetik rɔba O-ring dɛn . Dɛn kin pik dɛn tin ya fɔ di trɛnk ɛn di ebul we dɛn ebul fɔ handle prɛshɔn.

l Sayz dɛn: Wan SAE O-ring fes sil saiz chɔt de we de sho ɔl di difrɛn saiz O-ring dɛn we yu kin gɛt fɔ ORFS fitin dɛn. ORB fitin dɛn de fala di SAE stret UNF trɛd standad, we min se dɛn mek dɛn fɔ fit fayn fayn wan wit di uman trɛd pɔt pan bɔku mashin dɛn.

In shot, ORFS ɛn ORB ɔl tu dɛn mek fɔ bi supa adaptabl. Dɛn kin wok na bɔku difrɛn tin dɛn, ilɛksɛf na haydrolik hos asɛmbli ɔ fluid pawa paip sistem . Di men tin na dat, dɛn kin ɛp fɔ mek di mashin dɛn wok ɛn nɔ gɛt ɛni wata we de lik , we na big tin if yu want yu mashin fɔ las fɔ lɔng tɛm ɛn wok fayn.

Kɔmparativ Analysis: Lik Prɛvenshɔn ɛn Sefty

We wi de tɔk bɔt lik prɛvɛnshɔn na haydrolik sistɛm, wi de luk aw di O-ring fes sil (ORFS) ɛn di O-ring bɔs (ORB) de stɔp di wata fɔ rɔnawe fayn fayn wan. Dɛn kin yuz dɛn tu tin ya na haydrolik fitin fɔ mek tin dɛn tayt ɛn rayt, bɔt dɛn kin du am difrɛn we dɛn.

Lik Prɛvenshɔn Kapabiliti fɔ ORFS ɛn ORB

ORFS dεn no fכ dεn enkapsulεt O-ring we de sidon snug pan di flat silin sεf fכ di uman kכnεkshכn . We dɛn tayt di man fitin , dis O-ring kin squish jɔs rayt, we kin mek wan sil we nɔ de lik . I tan lɛk we yu put di lid pan jar supa tayt - nɔ spil!

Na di flip sayd, ORB gɛt wan sɛntetik rɔba O-ring we fit insay wan eria we gɛt grov na di bays pan di man trɛd . We yu skru di man trɛd insay di uman trɛd pɔt , di O-ring kin push insay di grov, we kin mek i tayt. Tink bɔt am lɛk we yu de push plɔg insay sɔkɛtɛ; i fit fayn fayn wan ɛn i nɔ de wig.

Sefty Kɔnsyus ɛn Aw Ɛni Fitin De Adrɛs Dɛn

Sefty na big tin, mɔ we wi de dil wit ay prɛshɔn pan tin dɛn lɛk haydrolik tubing ɛn hos asɛmbli . ɔl tu ORFS ɛn ORB gɛt fɔ handle dis prɛshɔn we dɛn nɔ giv ɔp.

ORFS na champs insay ay-prɛshɔn aplikeshɔn bikɔs dɛn mɛtal ɛn O-ring dɛbul sil rili de ol ɔp. Dɛn tan lɛk di supahiro dɛn we sil dɛn de mek, we de kip ɔlman sef frɔm lik we kin mek pɔsin slip ɔ faya na ples dɛn lɛk ɔf-road kɔnstrɔkshɔn ɔ mayning.

ORB , pan ɔl we i strɔng bak, i gɛt difrɛn we fɔ du tin. Di threaded portion ɛn O-ring combo min se i gud fɔ ay prɛshɔn , bak, bɔt i supa impɔtant fɔ gɛt di saiz ɛn fit jɔs rayt. If nɔto so, yu kin gɛt lik, ɛn nɔbɔdi nɔ want dat. I tan lɛk se yu mek shɔ se yu bayk ɛlmɛt fit bifo yu zoom dɔŋ wan il.

ɔl tu ORFS ɛn ORB de tek pan lik prɛvenshɔn ɛn sef insay dɛn yon we. ORFS kin gɛt di ed insay ay-prɛshɔn sityueshɔn bikɔs ɔf dɛn dabl sil , bɔt ORB stil na sɔlid chuk if yu mach ɔltin kɔrɛkt wan.

Tin dɛn fɔ Tink bɔt di Kɔst

We wi de tɔk bɔt O-Ring Face Seal (ORFS) ɛn O-Ring Boss (ORB) , wi de luk fɔ tu pɔpul kayn haydrolik fitin dɛn . Dɛn ɔl tu gɛt difrɛn tin dɛn we de afɛkt di kɔst. Lɛ wi dayv insay di fɔs kɔst dɛm ɛn di lɔng tɛm kɔst implikashɔn dɛm.

Initial Kost fɔ ORFS vs. ORB Fitin dɛn

ORFS fitin dɛn kin dia mɔ bifo tɛm. Dɛn gɛt flat say fɔ sidɔm ɛn wan chamfer we dɛn mek wit mashin fɔ ol di O-ring . Dis dizayn nid mɔ prɛsishɔn we dɛn de mek am. ORB fitin, wit dɛn threaded portion ɛn encapsulated O-ring , kin simpul ɛn bɔku tɛm dɛn nɔ kin tek bɔku mɔni we dɛn bigin.

Di Implikashɔn dɛn fɔ Kɔst fɔ Lɔng Tɛm

As tɛm de go, di kɔst kin chenj. ORFS fitin dɛn, wit dɛn mɛtal ɛn O-ring dabl sil , kin las fɔ lɔng tɛm. Dis min se dɛn nɔ go spɛn bɔku mɔni fɔ riples. ORB fitin dɛn, pan ɔl we dɛn kin shɔt fɔs, dɛn kin nid fɔ kia fɔ dɛn mɔ. Dɛn gɛt wan say we gɛt grov na di bays pan di man trɛd . If dis damej, lik kin apin.

Ɔl tu di O-ring fes sil fitin ɛn O-ring bɔs sil fitin gɛt dɛn yon silin we . ORFS de yuz flat siling surface , we ORB de yuz groove . Dis difrɛns kin afɛkt aw ɔltɛm yu nid fɔ chenj di pat dɛn.

Insay ay-prɛshɔn aplikeshɔn , lɛk insay wan industrial aplikeshɔn ɔ ɔf-road kɔnstrɔkshɔn , ORFS kin bɛtɛ. Dɛn mek dɛn fɔ ebul fɔ handle di prɛshɔn we dɛn de du we dɛn nɔ de mek lik pɔynt dɛn . So, dɛn kin sev yu mɔni pan mentenɛns insay di lɔng tɛm.

ORB fitin, na di ɔda say, fayn fɔ we yu nid sil we yu kin abop pan bɔt sɔntɛm yu nɔ gɛt di badjɛt fɔ ORFS. Dɛn kin yuz dɛn na bɔku say dɛn bak, lɛk haydrolik ɛkskavata , loda , fɔklift , ɛn trakta.

Fɔ Mek di Rayt Chɔch

We i kam pan haydrolik fitin, i rili impɔtant fɔ pik di rayt wan. Yu kin pik bitwin wan O-ring fes sil (ORFS) ɛn wan O-ring bɔs (ORB) . Dɛn ɔl tu gɛt dɛn yon bɛnifit. Na dis na wetin fɔ tink bɔt:

Tin dɛn we yu fɔ tink bɔt

1. Opareshɔn Prɛshɔn : ORFS fitin dɛn fayn fɔ ay prɛshɔn. Dɛn kin ebul fɔ handle mɔ fɔs we dɛn nɔ de lik.

2. Lik Point : ORB gɛt smɔl lik poɛnt. Dis na bikɔs di O-ring dɔn trɔp insay wan grov.

3. Sistem Dizayn : Tink bɔt di shep we yu sistɛm gɛt. ORFS gɛt flat say fɔ sidɔm, we nid mɔ ples.

4. Matirial : ORFS ɛn ORB ɔl tu kam insay matirial lɛk kabɔn, stenlɛs stiɛl , ɛn wit O-ring dɛn we dɛn mek wit Buna-n ɔ Viton.

5. Di we aw dɛn kin sidɔm : ORFS kin mek wan sil bay we dɛn kɔmprɛs wan O-ring. ORB de yuz wan pat we gɛt trɛd ɛn wan eria we dɛn mek wit chamfer mashin fɔ sial.

Sɛnario fɔ ORFS ɛn ORB

l ORFS : Pafɛkt fɔ flanged tubing ɛn kɔrosiv aplikeshɔn dɛn . Dɛn gɛt mɛtal ɛn O-ring dabl sil, we pɔsin kin rili abop pan.

l ORB : Gret fɔ we ples tayt. Dɛn gɛt man fit ɛn uman kɔnekshɔn we fit togɛda fayn fayn wan.

Kes Stɔdi : Insay wan haydrolik ɛkskavatɔ, dɛn bin de yuz ORFS fitin dɛn bikɔs dɛn bin ebul fɔ handle di ay-prɛshɔn aplikeshɔn dɛn ɛn dɛn bin izi fɔ mentenɛns.

Fact : Akɔdin to standad lɛk SAE J1453 ɛn ISO 8434-3 , ORFS dɛn mek fɔ pul lik dɛn na haydrolik hos asɛmbli.

Quote : 'Insay wi ɛkspiriɛns, ORFS fitin dɛn dɔn ridyus di fluid lik na NPT pɔt dɛn bad bad wan ,' na so wan sɛls tim ɛkspɛkt frɔm wan big haydrolik adapt kɔmni se.

We yu de pik, mɛmba se ORFS kin bɛtɛ fɔ ay prɛshɔn ɛn we yu nid sistɛm we nɔ de lik . ORB kin bi di choice fɔ tayt ples ɛn smɔl lik poɛnt.

Di rayt fitin de mek yu haydrolik aplikeshɔn dɛn de rɔn fayn fayn wan. Na bɔt di kwaliti kɔmpɔnɛnt dɛn ɛn di sistɛm efyushɔn . So, we yu de disayd, tink bɔt di sil fitin dɛn , SAE O-ring fes sil saiz chɔt , ɛn di difrɛn saiz O-ring we yu go nid.

Fɔ industrial aplikeshɔn lɛk fɔklift, trakta , ɔ valv , yu want fɔ mek shɔ se yu gɛt di rayt sil. Ilɛksɛf na ORFS ɔ ORB , ɛni wan pan dɛn gɛt in ples. Mek shɔ se yu chɛk yu sistɛm in nid ɛn pik di fitin we go mach dɛn nid dɛn de bɛst.

FAQ dɛn bɔt ORFS ɛn ORB Fitin dɛn

Wetin difrɛns ORFS fitin frɔm ORB pan tin dɛn we gɛt fɔ du wit silin prɛshɔn?

O-ring fes sil (ORFS) fitin fɔ dɛn Dɛn sabi ay-prɛshɔn kapabiliti. Dɛn gɛt wan flat say we dɛn kin sidɔm we kin kɔmprɛs wan O-ring , we kin mek dɛn sidɔm tayt . Difrɛn frɔm dat, O-ring bɔs (ORB) fitin dɛn de yuz wan pat we gɛt trɛd ɛn sintetik rɔba O-ring fɔ sial, we kin wok fayn bɔt i nɔ kin mach di silin prɛshɔn we ORFS gɛt insay sɔm kes dɛn.

Yu tink se dɛn kin yuz ORB fitin dɛn insay di ples fɔ ORFS na say dɛn we gɛt ay vaybreshɔn?

ORB fitin, wit dɛn SAE stret UNF trɛd , na strɔng. Bɔt, insay ay-vaybreshɔn ɛnvayrɔmɛnt , ORFS fitin dɛn kin bɛtɛ bikɔs dɛn mɛtal ɛn O-ring dɛbul sil de ridyus di risk fɔ lik.

Aw di kɔst-ɛfɛktiv we ORFS gɛt kɔmpia to ORB fɔ lɔng tɛm?

As tɛm de go, ORFS kin bi mɔ kɔst-ɛfɛktiv bikɔs ɔf dɛn lɔng savis layf ɛn nɔ-lik pefɔmɛns. ORB fitin dɛn kin nid mɔ mentenɛns , mɔ na ay-prɛshɔn aplikeshɔn dɛn.

Sɔm patikyula industri dɛn de we lɛk ORFS pas ORB, ɛn wetin mek?

Yes, industri dɛm lɛk ɔf-road kɔnstrɔkshɔn ɛn mayning kin lɛk ORFS fɔ dɛn durabiliti insay ay-prɛshɔn ɛn kɔrosiv aplikeshɔn dɛm . Dɛn kin ebul fɔ handle ɔpreshɔn prɛshɔn wit smɔl lik pɔynt dɛn.

Wetin na di men tin dɛn we yu fɔ tink bɔt fɔ sef we yu de pik bitwin ORFS ɛn ORB fitin dɛn?

Sef na di men tin. ORFS fitin dɛn de gi wan sil we pɔsin kin abop pan , we de ridyus di risk fɔ mek wata lik . ORB fitin dɛn fɔ instɔl kɔrɛkt wan fɔ mek shɔ se dɛn sef, mɔ na ay-prɛshɔn sistem.

Aw di tɛmpracha we de chenj kin ambɔg di chukchuk bitwin ORFS ɛn ORB?

Di chenj we di tɛmpracha chenj kin afɛkt di fitin dɛn. ORFS fitin dɛn gɛt wan strɔng dizayn we de bia fayn wit tɛmpracha varyans, we de mek dɛn kɔntinyu fɔ gɛt tayt sil . ORB kin nid fɔ pe atɛnshɔn mɔ fɔ mek shɔ se di O-ring nɔ de fel ɔnda di tɛmpracha we pasmak.

Wetin na di tipik mentenɛns chalenj dɛn we gɛt fɔ du wit ORB fitin dɛn?

Mentɛnans fɔ ORB fitin dɛn kin inklud fɔ chɛk di O-ring dɛn fɔ si if dɛn west ɛn fɔ mek shɔ se di trɛd dɛn nɔ pwɛl. We yu de chɛk ɔltɛm, dat kin ɛp fɔ mek di wata nɔ lik.

Insay us sityueshɔn dɛn go tek ORFS fitin se i nɔ fayn pas ORB?

ORFS fitin kin bi less suitable wen limited space de bikos dem bulkier. ORB fitin dɛn gɛt smɔl profayl, we de mek dɛn fit fayn fɔ tayt ples.

Aw di matirial opshɔn fɔ ORFS ɛn ORB fitin dɛn difrɛn?

Matirial dɛn lɛk kabɔn, kabɔn we dɛn plet nikel , ɛn stenlɛs stiɛl na tin dɛn we dɛn kin yuz fɔ ɔl tu. Bɔt stil, ORFS fitin dɛn kin yuz Buna-n ɔ Viton fɔ O-ring dɛn, we ORB gɛt difrɛn saiz O-ring opshɔn dɛn fɔ fit di eria we gɛt grov.

Us instɔleshɔn tips kin ɛp fɔ mek shɔ se yu sial fayn wit ORFS ɛn ORB fitin dɛn?

Fɔ mek yu ebul fɔ sidɔm fayn, mek shɔ se di say dɛn we yu de sidɔm klin. Fɔ ORFS, alaynɛ di flat silin sɔfays kɔrɛkt wan. Fɔ ORB, mek shɔ se di O-ring sidɔm rayt na di say we gɛt grov ɛn nɔ pinch am we dɛn de instɔl am.

Yu tink se dɛn kin chenj ORFS ɛn ORB Fitin dɛn?

Jɛnɛral wan, nɔ. ORFS ɛn ORB gɛt difrɛn we fɔ thread ɛn sial . If yu yuz di rɔng kayn, i kin mek yu lik ɛn gɛt prɔblɛm wit sef . Chek ɔltɛm wit yu sɛl tim ɔ kɔntakt ditil dɛn we di wan we mek am gi fɔ gayd yu.

Kɔnklushɔn: Fɔ mek shɔ se dɛn du di wok fayn fayn wan na di Haydrolik Sistɛm dɛn

Insay dis atikul, wi dɔn fɛn di difrɛns bitwin O-ring fes sil (ORFS) ɛn O-ring bɔs (ORB) fitin dɛn. Na dis na wan kwik sɔmari fɔ wetin wi dɔn lan:

l ORFS fitin dɛn gɛt flat silin sɔfa ɛn chamfer we dɛn mek wit mashin we de ol wan O-ring na in ples.

l ORB fitin dεm gεt pat we gεt tכd εn dεn de yuz O-ring we dεn put na di grov εria na di bכs pan di man tכd fכ mek wan sil.

Sɔma fɔ di Ki Takeaways

l O-ring fes sil fitin na fayn tin fɔ ay-prɛshɔn aplikeshɔn ɛn i de ɛp fɔ mek i nɔ lik.

l O-ring bos sil fitin na versatile ɛn dɛn kin yuz am na difrɛn industrial aplikeshɔn dɛn.

l Di SAE J1453 ɛn ISO 8434-3 standad dɛn de gayd di yus fɔ dɛn fitin ya.

Bɛst Prɛktis fɔ Pik ɛn Mentɛn O-Ring Fitin dɛn

We yu de pik di rayt fitin fɔ yu haydrolik sistem dɛn , tink bɔt dɛn bɛst we ya:

1. No Yu Aplikeshɔn : Difrɛn sistɛm dɛn nid difrɛn fitin dɛn. Fɔ ɛgzampul, ORFS bɔku tɛm na dɛn kin yuz ɔf-road kɔnstrɔkshɔn ɛn mayning bikɔs i de handle ay prɛshɔn fayn fayn wan.

2. Chek di Matirial dɛn : Fitin dɛn gɛt kabɔn, kabɔn we dɛn plet nikel , ɛn stenlɛs stiɛl . Dɛn kin mek O-ring dɛn wit tin dɛn lɛk Buna-n ɛn Viton . Pik di wan we fit yu sistɛm in nid.

3. Yuz di Rayt Sayz : Mek shɔ se yu yuz SAE O-ring fes sil saiz chɔt fɔ fɛn di kɔrɛkt saiz O-ring fɔ fit fayn fayn wan.

4. Mentɛnans ɔltɛm : Chek yu O-ring fitin dɛn fɔ si if dɛn dɔn west ɛn rɔtin. Riples dɛn if dɛn sho sayn dɛn fɔ se dɛn dɔn pwɛl fɔ mek dɛn nɔ lik.

5. Kɔnsul Ɛkspɛkt dɛn : If yu nɔ shɔ, tɔk to yu sɛl tim ɔ kɔntak di haydrolik adapt ɛn tubing saplay dɛn fɔ advays.

Mɛmba se, ilɛksɛf yu de wok pan haydrolik ɛkskavatɔ , loda , fɔklift , ɔ trakta , di rayt we fɔ sidɔm kin min di difrɛns bitwin wan we nɔ de lik ɛn wan we gɛt prɔblɛm. sistem

We yu de mek yu fitin dɛn fayn:

l Inspɛkt di say dɛn we dɛn kin sidɔm ɔltɛm fɔ si if dɛn dɔn pwɛl.

l Mek shɔ se di sintetik rɔba O-ring dɛn nɔ gɛt kɔt ɛn nɔ defɔm.

l Tayt di fitin dɛn to di spesifikeshɔn dɛn we dɛn dɔn rɛkɔmɛnd fɔ avɔyd fɔ kɔmprɛs di O-ring pasmak.

We yu fala dɛn tin ya, yu kin ɛp fɔ mek shɔ se de wok fayn ɛn lɔng savis layf yu haydrolik sistem dɛn . Ɔltɛm prɔyoritɛt kwaliti kɔmpɔnɛnt dɛn fɔ mek di sistɛm kɔntinyu fɔ wok fayn . Mɛmba se di gol na fɔ mek yu sistɛm de rɔn witout ɛni fluid lik ɔ lik pɔynt.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu